DOING waste plastic oil pyrolysis system can process both conventional plastic and unconventional plastics. The final products of waste plastic pyrolysis system are high calorific value fuel oil, syn-gas, carbon black, etc.

DOING waste plastic oil pyrolysis system can process a wide range of waste plastic materials, including conventional plastics like PP, PE, ABS, PS, etc., as well as unconventional plastics like paper mill scraps, aluminum plastic, acrylic, agricultural mulch, wind turbine blade scraps, photovoltaic panels, cable skin, circuit boards, tooth paste tubes, vehicle bumpers, glass fiber, domestic waste, medical waste, electronic waste, construction waste, nylon, etc.

DOING waste plastic oil pyrolysis system for sale

DOING waste plastic oil pyrolysis system for sale

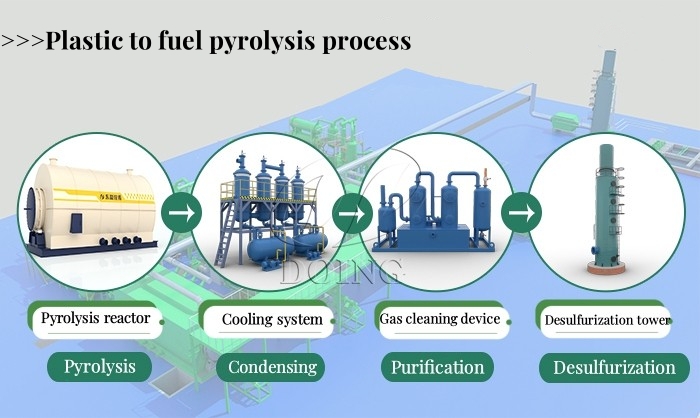

Process flow of waste plastic oil pyrolysis system:

1. The waste plastic raw materials enter the core pyrolysis container- pyrolysis reactor through (manual conveying/automatic feeder conveying/auger conveying).

2. Then, the system starts the pyrolysis process, (the burner/hot air furnace) continuously heats the waste plastic. At this stage, the waste plastic material is gradually converted into gaseous state under the action of high temperature.

3. Then through the high-efficiency heat exchange technology, the oil gas is condensed and recovered in the multi-stage condensation system. This series of operations can be performed using automated PLC to ensure the effective collection of oil gas and the recycling of energy.

4. At the end of the waste plastic oil production process, the solid residue after plastic oil pyrolysis process, carbon black, is continuously discharged through the built-in automatic slag discharge system and collected in a specific container, realizing the continuous automation of waste management.

5. Finally, the flue gas generated during the pyrolysis process needs to be precisely treated by the desulfurization and denitrification equipment to ensure that the emission standards meet environmental protection requirements, thereby completing the clean emission of flue gas.

Waste plastic to oil pyrolysis system process flow

Waste plastic to oil pyrolysis system process flow

Advantages of DOING’s waste plastic oil pyrolysis system:

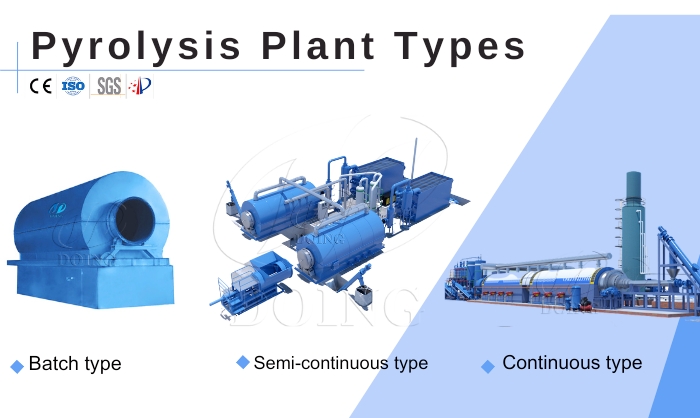

1. A variety of models are available: batch waste plastic oil pyrolysis system---1 furnace per day, semi-continuous waste plastic oil pyrolysis system---2 furnaces per day, and fully automatic continuous waste plastic oil pyrolysis system---24 hours a day for more than 40 days. Different models of waste plastic oil pyrolysis systems have different configurations and different plastic feeding requirements.

Batch/Semi-continuous/Fully Continuous waste plastic to oil pyrolysis systems

Batch/Semi-continuous/Fully Continuous waste plastic to oil pyrolysis systems

2. Decoking and dewaxing technology

Henan Doing Company experienced technical team and engineering team, which can configure different design schemes based on the investor's raw material selection.

①Decoking of waste plastic oil pyrolysis system:

A. Optional materials, a variety of equipment materials can be selected, such as Q245R, Q345R boiler plate/ stainless steel, etc., optional equipment thickness, optional anti-coking materials.

B. Match waste plastic selection equipment to remove acidic plastics in advance.

C. A variety of equipment auxiliary assemblies such as energy storage balls and decoking devices are optional.

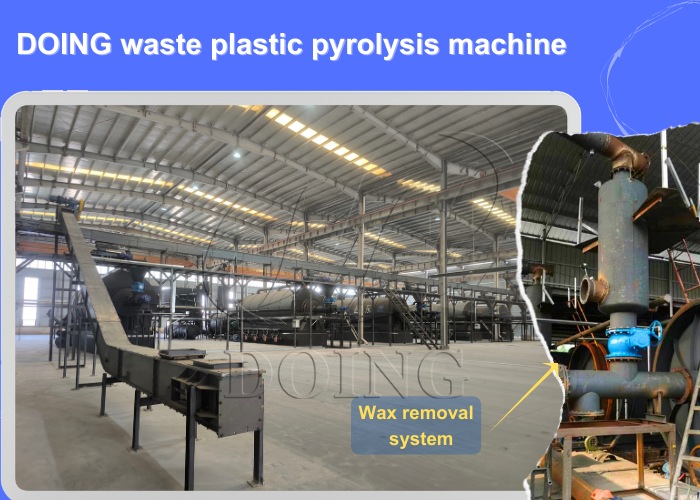

②Dewaxing of waste plastic oil pyrolysis system:

A.Customized adjustment of equipment pipelines and equipment processes.

B.Configure dewaxing tanks.

Dewaxing system of DOING plastic oil pyrolysis system

Dewaxing system of DOING plastic oil pyrolysis system

Waste plastic oil making equipment manufacturer

Henan Doing Environmental Protection Technology Co., Ltd.(referred to HENAN DOING), is a subsidiary of DOING HOLDINGS, dedicated to the production of environmentally friendly waste tire/ plastic/ oily sludge pyrolysis systems, with multiple patented technologies and government-recognized high-tech enterprises.

Henan Doing Company-pyroysis system manufacturer

Henan Doing Company-pyroysis system manufacturer

Recently, DOING Brand Continuous Pyrolysis System has also been selected into the Catalogue of Energy-saving, Water-saving and Solid Waste Comprehensive Utilization Technologies and Equipment in the Industrial Field of Henan Province (2024 Edition) published by the government, demonstrating the brand strength and equipment advantages.

For waste plastic recycling pyrolysis projects with good development prospects, Henan Doing Company has supplied and installed many sets of waste plastic oil pyrolysis systems for our customers from China, India, Japan, Indonesia, Vietnam, Thailand, Mexico, Brazil, Colombia, Fiji, the Philippines, South Africa, Canada, etc.

Project 1: 10 sets of semi-continuous plastic oil pyrolysis systems in Vietnam

Waste plastic oil pyrolysis systems installed in Vietnam

Waste plastic oil pyrolysis systems installed in Vietnam

Project 2: 5 sets of semi-continuous waste plastic oil pyrolysis systems in China

Semi-continuous plastic oil pyrolysis system installed in China

Semi-continuous plastic oil pyrolysis system installed in China

Project 3: 12Ton Batch plastic oil pyrolysis system in Indonesia

Scrap plastic oil pyrolysis system operated in Indonesia

Scrap plastic oil pyrolysis system operated in Indonesia

Project 4: 15Ton waste plastic oil pyrolysis system and plastic oil to diesel distillation system in Japan

Waste plastic to diesel pyrolysis distillation systems in Japan

Waste plastic to diesel pyrolysis distillation systems in Japan

Through continuous innovation and quality improvement, Henan Doing Company has become the reliable and preferred manufacturer of plastic oil pyrolysis system in the global market. If you want to engage in the waste plastic to fuel oil recycling pyrolysis business, welcome to contact us for suitable pyrolysis system solution and all-series of technical services.

Waste Plastic Pyrolysis Plant Flow Chart

Converting Plastic Oil to Diesel Flow Chart

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.