DOING waste plastic tp fuel pyrolysis reactor is designed for recycling and converting waste plastic waste into fuel oil, carbon black, and syn-gas. DY-plastic to fuel pyrolysis reactor has mature working process and high machine quality.

By converting plastic waste into useful fuel oil, syn-gas and carbon black products, plastic pyrolysis reactor promotes sustainable waste management practices. Instead of disposing of plastic waste in landfills or incinerators, it is processed into useful products, reducing the waste plastic pollution and promoting resource efficiency.

DOING waste plastic to fuel pyrolysis reactor for sale

DOING waste plastic to fuel pyrolysis reactor for sale

1.What's plastic to fuel pyrolysis reactor?

Waste plastic to fuel pyrolysis reactor is a type of waste plastic recycling machine used to turn plastic into useful products through a process called pyrolysis/cracking. Plastic pyrolysis is a thermal decomposition process that breaks down waste plastic into smaller molecules such as fuel oil, syn-gas, and carbon black in the absence of oxygen.

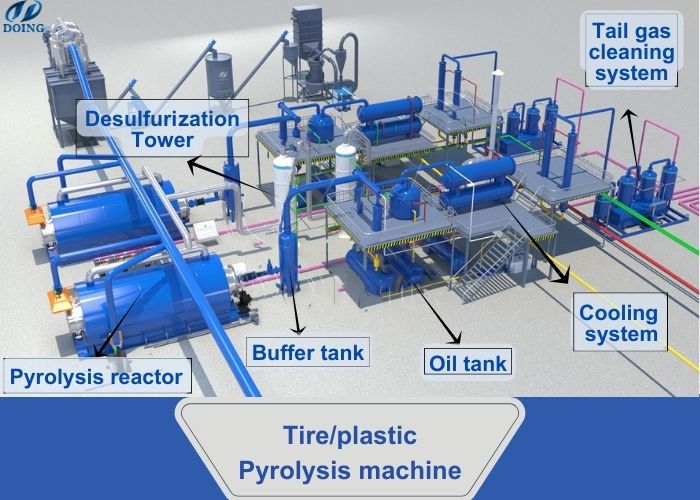

A complete system of waste plastic to fuel pyrolysis reactor typically consists of several key components: reactor heating system, pyrolysis reactor chamber, oil gas condenser system, circulation cooling water system, syn-gas recycling system, exhaust gas cleaning system, carbon black discharge system.

Waste plastic to fuel pyrolysis system components

Waste plastic to fuel pyrolysis system components

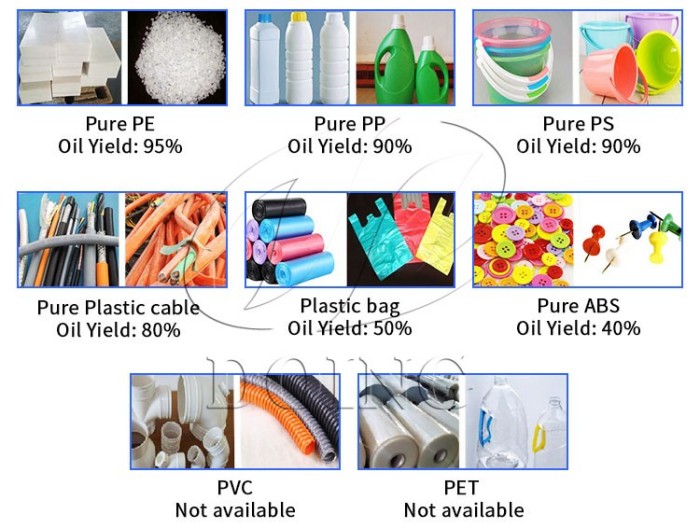

2.What type of waste plastic is best for pyrolysis into fuel oil?

Henan Doing DY-waste plastic to fuel pyrolysis reactor can process a wide range of raw materials, including conventional plastics: PP, PE(HDPE/LDPE), ABS, PS, etc., as well as unconventional plastics: paper mill scraps, aluminum plastics, acrylic, pmma, agricultural mulch/plastic films, plastic sheet, vehicle bumpers, fan blade scraps, photovoltaic panels, cable skins, circuit boards, glass fibers, domestic waste, medical waste, electronic waste, construction waste, nylon, etc., and waste rubber tires, waste oil sludge, coal tar residue, oil-containing contaminants, etc. can all be processed.

Waste plastic pyrolysis reactor feedstocks and oil yields

Waste plastic pyrolysis reactor feedstocks and oil yields

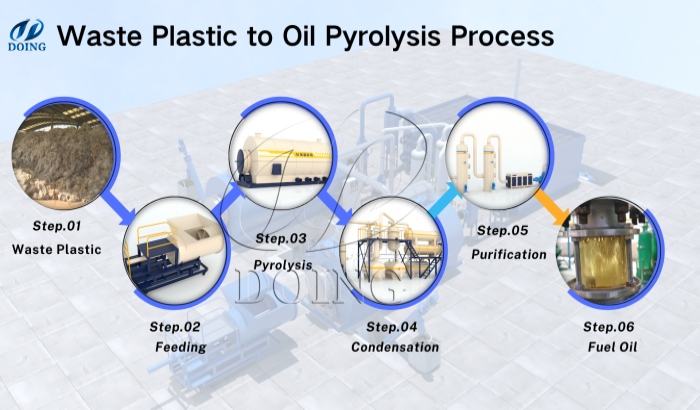

3.How does waste plastic to fuel pyrolysis reactor work?

The working process flow of DY-waste plastic to fuel pyrolysis reactor is as follows:

First, the waste plastic raw materials enter the core pyrolysis container-reactor through (manual conveying/automatic feeder conveying/auger conveying).

Then, the pyrolysis system starts the cracking program, the burner/hot air furnace will continuously heat the waste plastic and circulates the operation to successfully complete the pyrolysis process. At this stage, the waste plastic material is gradually converted into gaseous state under the action of high temperature.

And then the oil gas are condensed and recovered in the condensation system, and the usable syn-gas fuel is separated. This series of operations can be carried out by automated PLC to ensure the effective collection of oil gas and the recycling of energy.

At the end of the waste plastic oil production process, the solid residue after pyrolysis, carbon black, is continuously discharged through the automatic slag discharge system and collected.

Finally, the exhaust gas generated during the plastic to fuel pyrolysis process needs to be precisely treated by the desulfurization and denitrification equipment to ensure that the emission standards meet the environmental protection requirements, so as to complete the standard emission.

Waste plastic pyrolysis to fuel oil production process

Waste plastic pyrolysis to fuel oil production process

4.Advantages of DOING waste plastic to fuel pyrolysis reactor for sale:

①A variety of models are available: batch waste plastic reactor that completes 1 furnace per day, semi-continuous plastic pyrolysis reactor that can complete 3 furnaces in 2 days, and fully continuous waste plastic pyrolysis reactor that can run 24 hours a day for more than 40 days. Different models of waste plastic to fuel pyrolysis reactors have different functions and different degrees of environmental protection. Their processing capacities vary from small scale 100kg per batch to 50ton/set per day.

Batch continuous plastic to fuel pyrolysis reactors

Batch continuous plastic to fuel pyrolysis reactors

②Decoking and waxing technology: Henan Doing has professional technical team and an engineering team, which can configure different design schemes based on the investor's raw material selection, including special designed decoking and dewaxing systems of waste plastic to fuel pyrolysis reactor.

③Reliable machine quality: DOING waste plastic to fuel pyrolysis reactor is a popular and preferential choice for many waste plastic recycling business investors due to its advanced technology and design, high-quality reactor fabrication materials and stable construction, user-friendly operation and maintenance, efficient performance, and energy-saving features. Besides that, it is also certified by ISO, CE, and can meet the environment impact assessment(EIA) standards of many countries, even the EU standard.

5.Reliable Waste plastic to fuel pyrolysis reactor manufacturer

Henan Doing Environmental Protection Technology Co., Ltd is a subsidiary of Dongying Holdings, dedicated to the production of environmentally friendly waste tire/plastic/oil sludge to fuel pyrolysis reactor, with many patented technologies and fruitful results. DOING Company got many certificates and recognizance from the government, including “High-Tech Enterprise”, “Innovative enterprise”, etc. And DOING continuous pyrolysis reactor has also been enlisted into the "Industrial Energy Saving, Water Saving and Solid Waste Comprehensive Utilization Technology Equipment Catalog (2024 Edition)", demonstrating the brand strength and equipment advantages.

China Henan DOING pyrolysis reactor manufacturer factory display

China Henan DOING pyrolysis reactor manufacturer factory display

For the waste plastic to fuel oil pyrolysis production projects , Henan Doing Company can provide different solutions of pyrolysis reactors, to meet the various needs of project investors. We DOING company have a vertically integrated production system to ensure the consistency of product quality and timely delivery. At the same time, our company has established a professional after-sales service team that can respond to customer needs in a timely manner, provide on-site installation, commissioning, maintenance, tracking and feedback services, and provide a one-stop comprehensive solution.

Waste to fuel pyrolysis reactor processing sites installed by DOING

Waste to fuel pyrolysis reactor processing sites installed by DOING

Henan Doing's thermal pyrlysis plant reactor not only has many project operation sites in China, but also has stable project operation sites in Africa, North America, South America, Southeast Asia, Oceania, Europe and other regions. DY-waste plastic to fuel pyrolysis reactors have been hot sold to Mexico, Japan, Brazil, India, Vietnam, Thailand, the Philippines, South Africa, Fiji, Canada, etc. Through continuous innovation and quality improvement, Henan Doing has established a good brand image in the global market, becoming a reliable and world-leading pyrolysis reactor manufacturer and supplier.

Waste Plastic Pyrolysis Plant Flow Chart

Converting Plastic Oil to Diesel Flow Chart

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.