Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Plastic is a valuable waste resource in our daily life. Normally we can convert it into diesel through pyrolysis process and distillation process. The oil yield totally depends on the raw material what exactly types and purity. For the whole process of converting plastic into diesel fuel, we need two machines: waste plastic pyrolysis machine to convert plastic into pyrolysis oil, pyrolysis oil to diesel distillation machine to convert pyrolysis oil to diesel.

Convert plastic to diesel pyrolysis distillation machine

Convert plastic to diesel pyrolysis distillation machine

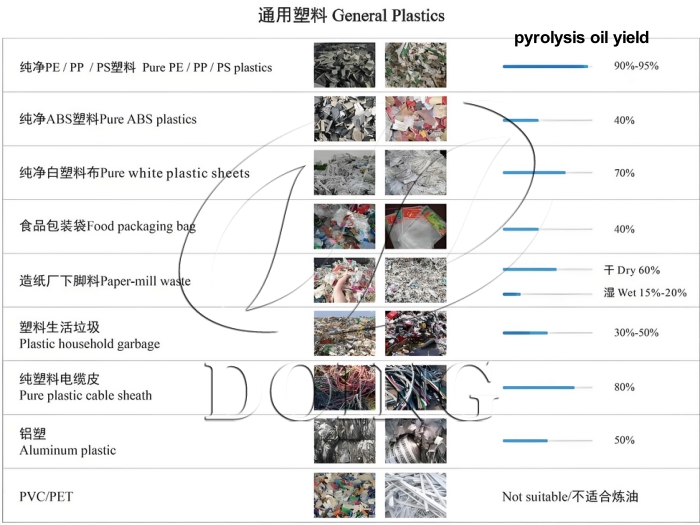

Pyrolysis process: Pyrolysis technology is the industrial process of breaking down large molecules of plastic into smaller molecules of oil, gas and carbon black, that is to say, pyrolysis technology of plastic is the inverse process of manufacturing plastic products by crude oil materials. The pyrolysis technology of waste plastic not only causes no pollution to the environment but also recycles energy effectively. In this stage, the oil yield depends on the types and purity of plastics, which generally varies from 35% to 95%. So if you want to get a high oil yield, you'd better select the pure PP/PE/PS/ABS plastics as raw materials, which has the highest oil yield between 90% and 95% among all plastic waste.

Oil yields of various plastics

Oil yields of various plastics

Distillation process: Normally distillation machine can refine fuel oil, like plastic pyrolysis oil, tyre pyrolysis oil and used lube oil, wastes engine oil into diesel. This kind of diesel is the non-standard diesel, but also has wide applications to be used in diesel generators, trucks, tractors, ships, boilers and so on. In this stage, the purifying oil yield is about 85% to 90%.

Therefore, the oil yield of converting plastic into diesel is 85%-90% of the plastic oil yield.

Also, in addition to the plastic itself, pyrolysis and distillation machines are also the other important factor affecting the oil yield. Commonly, the more advanced the pyrolysis and distillation technology, the better the condensation configuration of the equipment can convert plastic into diesel at a higher oil yield.

DOING waste plastic to diesel machine for sale

DOING waste plastic to diesel machine for sale

DOING waste plastic pyrolysis machine and pyrolysis oil to diesel distillation machine both adopt the latest technology and best configurations to ensure the excellent performance of the whole process of converting plastic into diesel.

DOING waste plastic pyrolysis machine adopts the latest pyrolysis technology and is equipped with the fully automatic PLC control system, which can precisely control the heating and pyrolysis temperature to ensure the full pyrolysis of platsics. And for the cooling system, DOING has two choices, which both have industrial cooling effect to get as much oil as possible. As for the pyrolysis oil to diesel distillation machine, there are also updated improvements and testing on the performance of the distillation temperature control and cooling system to maximize the oil yield while ensuring the quality of the obtained diesel fuel.

DOING pyrolysis machine and distillation machine projects

DOING pyrolysis machine and distillation machine projects

DOING waste plastic pyrolysis machine and pyrolysis oil to diesel distillation machine has been successfully put into operation in many countries and received good feedback, and our customers are also satisfied with the final oil yield and oil quality. The following video is one real running site of DOING pyrolysis oil to diesel distillation machine, as the video displays, the obtained diesel fuel has good quality:

Now converting plastic to diesel fuel has become a popular business for waste plastic recycling, which can make full utilization of plastic. If you also want to invest in the business, just feel free to contact DOING. We can provide various types of equipment for you with different configurations to meet your different requirements.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.