Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

In Singapore, there are still some problems in the waste plastic treatment and recycling industry, that's the waste plastic hasn't been reasonably and effectively disposed of. There is currently a technology that can treat waste plastic into fuel, carbon black, and other energy sources. This is pyrolysis technology, which offers good solutions for Singapore to treat and recycle waste plastics. This article will introduce the process of DOING waste plastic treat pyrolysis machine and why is it an effective way for Singapore to treat waste plastic?

Placing waste plastic under anaerobic and high-temperature conditions, under the combined action of decomposition and condensation, macromolecular organic compounds will undergo pyrolysis and transform into gaseous, liquid, and solid components with relatively small molecular weights. The transformation process of organic compounds under these conditions is called pyrolysis.

DOING waste plastic treat pyrolysis plant

DOING waste plastic treat pyrolysis plant

1). The first step is feeding, feeding the waste plastic into the pyrolysis rector.

2). The second step is heating. After the feeding is completed, the combustion burners need to be opened to heat the reactor. Next, waste plastic will be converted into oil-gas, and it's the oil-gas output stage.

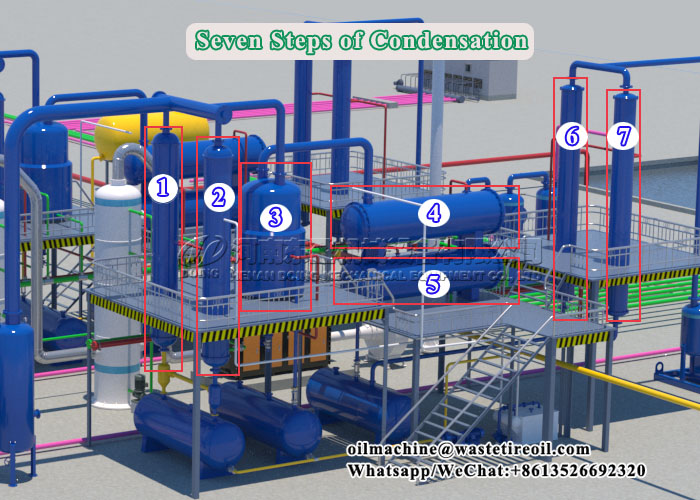

3) The third step is the condensation stage, the oil-gas will through our cooling system and cool into the fuel oil and non-condensable gas. All condensers use circulating cooling water, achieving zero discharge of wastewater.

The cooling system of DOING waste plastic pyrolysis machine

The cooling system of DOING waste plastic pyrolysis machine

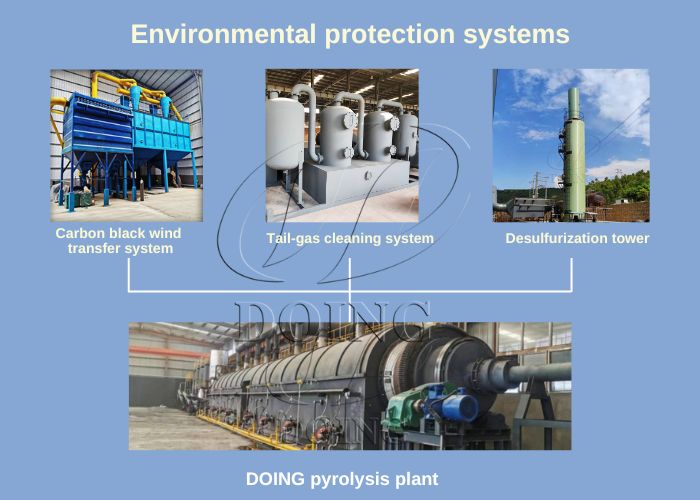

4). The fourth step is by-product collection and exhaust gas treatment.

The fuel oil and carbon black will be collected for sale or deep processing. It is worth mentioning that our environmental control system, which uses a water mist dust collector to remove sulfur dioxide gas and solid particles from the flue gas. It not only achieves standard flue gas emissions but also extends the service life of the reactor.

That's the process of DOING waste plastic treat pyrolysis machines. Besides, the following will show the process for you to understand with the on-site operation video of our Ecuadorian customer's waste plastic pyrolysis plants:

Firstly, the waste plastic pyrolysis machine promotes resource conservation and circular economy principles. The extracted oil and gas from plastic waste can be used as alternative energy sources, reducing the dependence on fossil fuels. Additionally, the carbon black obtained can be used as a substitute for carbon-based materials in various industries.

Secondly, pyrolysis helps to reduce the volume of plastic waste significantly. As plastic is converted into liquid or gaseous form during the process, it occupies much less space compared to its original form, easing the burden on landfills.

The environmental protection system of waste plastic pyrolysis machine

The environmental protection system of waste plastic pyrolysis machine

Lastly, pyrolysis offers environmental benefits by minimizing the release of harmful emissions. With proper control systems, the process can be optimized to prevent the release of toxic gases into the atmosphere. This is crucial for Singapore, as it aims to maintain a clean and sustainable environment.

Overall, pyrolysis machines present a promising solution for Singapore to effectively treat waste plastics, minimize environmental impact, and create value from what was once considered as disposable material. If you want to do this waste plastic pyrolysis project in Singapore, please feel free to contact us at any time.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.