Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

With the recent rebound in the popularity of pyrolysis plant projects in Southeast Asia, more and more people want to install pyrolysis plants in their countries, like Indonesia, Thailand, Singapore, etc. This passage will take Indonesia as an example to make a detailed introduction about how to install a pyrolysis plant in Indonesia:

The first step is to conduct market research to confirm the raw material you want to process and get a steady supply. Different raw materials can get different final products. Take the waste tire as an example, we can get fuel oil, carbon black, steel wire and combustible gas, which have different costs in different countries. So before installing pyrolysis plant in Indonesia, you can have a brief learning about the market of raw materials and final products to reach the maximum benefits.

Raw materials suitable for pyrolysis plant

Raw materials suitable for pyrolysis plant

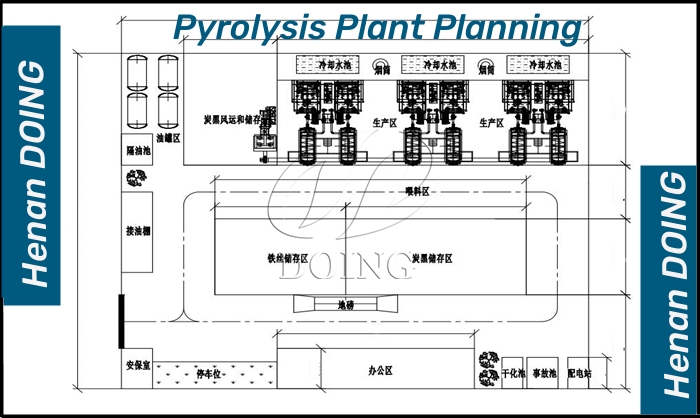

The second step is to select a suitable land and get environmental permission. Generally, factories are built in industrial parks. If you have already selected the suitable land, the next step is to obtain the industrial land permit approval for the land. Pyrolysis plants with different processing capacities occupy different areas, such as small pyrolysis plants with a capacity of 100-500kg/day, which occupy an area of 15 square meters, and the most common and popular 15tpd pyrolysis plant, a single unit covers an area of 300 square meters. Of course, the entire factory building also needs to have clear planning, including office areas, raw material storage areas, oil tank areas, etc. We can provide you with professional and standardized factory project layouts if you need.

Pyrolysis plant planning drawing

Pyrolysis plant planning drawing

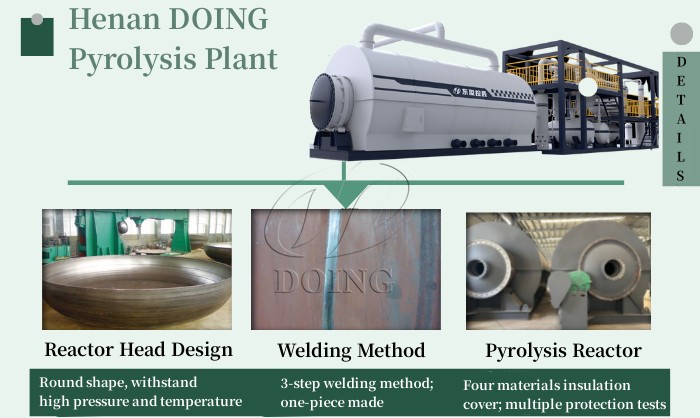

The third step is to choose a reliable supplier and configure appropriate pyrolysis plant solutions based on your needs and local conditions. The reliable supplier should offer advanced technologies and pyrolysis plants, including raw material pretreatment system, pyrolysis reactor, cooling system, exhaust gas treatment system, and final products collecting system. The quality and designs of these components play a vital role in ensuring smooth operation, maximizing product yield, and minimizing environmental impact.

Design details of DOING pyrolysis plant

Design details of DOING pyrolysis plant

Additionally, when the customer receives the pyrolysis plant and needs to install it, we also can arrange our engineer to the customer's factory to guide the installation and train the workers.

Also, before installing the pyrolysis plant in Indonesia, you can have a brief learning about the local policy for the pyrolysis plant projects, such as the loans, subsidies, etc.

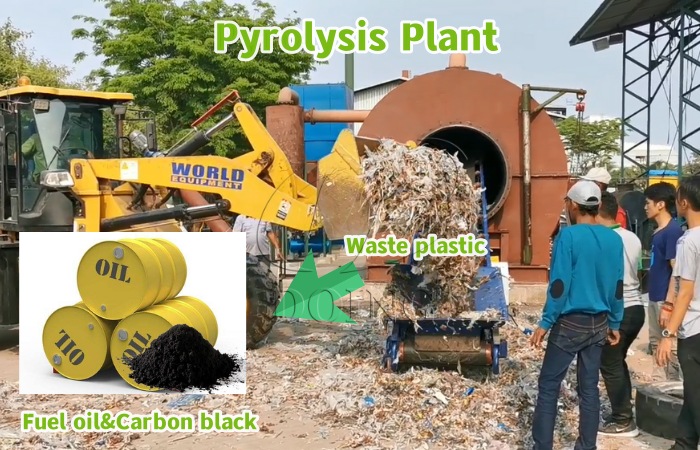

DOING pyrolysis plant project in Indonesia

DOING pyrolysis plant project in Indonesia

In a word, installing a pyrolysis plant in Indonesia is a popular and profitable investment. If you are interested in installing pyrolysis plants in Indonesia, just feel free to contact us, for we have cooperated with many Indonesian customers on our pyrolysis plants and have abundant experience. For example, we just delivered a set of waste plastic pyrolysis plant to Indonesia two months ago. So more details about this, welcome to leave a message.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.