Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

The price of pyrolysis machine is about from 20000usd to 750,000usd different, which is influenced by several key factors, such as pyrolysis machine types, capacities, configurations, etc., which can not only affect the pyrolysis machine price, but also affect the working performance of the pyrolysis machine.

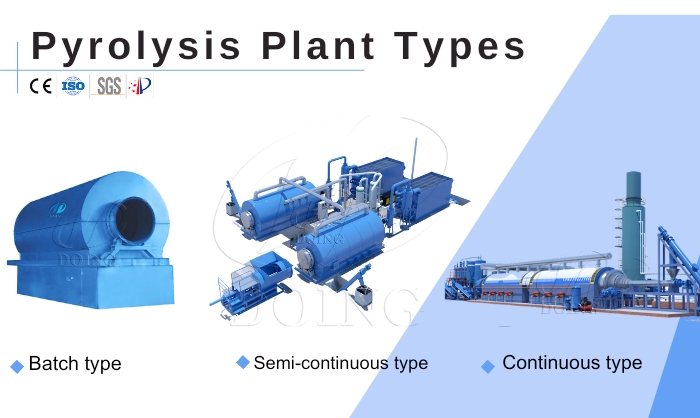

1. Pyrolysis machine types

DOING has various types of pyrolysis machines, including batch type, semi-continuous type, and fully continuous type. Each type has its own advantages and disadvantages, which can affect the price. Take the continuous pyrolysis machine as an example, it has bigger processing capacity and higher working automation and efficiency, so its price will be higher than the batch type.

Three types of DOING pyrolysis machines for sale

Three types of DOING pyrolysis machines for sale

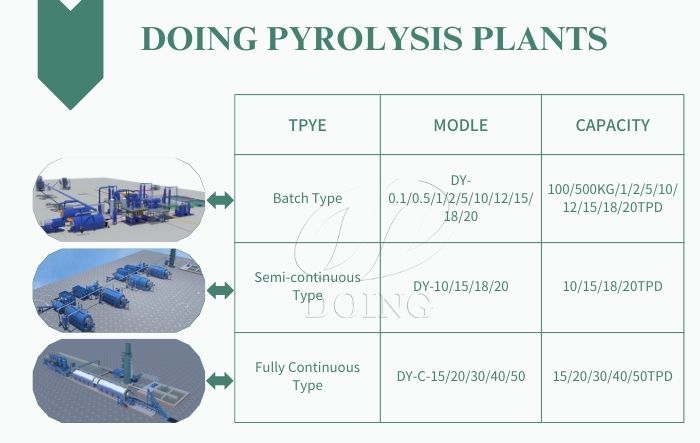

2. Pyrolysis machine capacity

Pyrolysis machines come in different sizes and capacities, ranging from small-scale machines that can process one hundred kilograms of waste per day to large-scale plants that can handle 50 tons of waste daily. The larger the capacity, the higher the price tag.

Different capacities of DOING pyrolysis machines

Different capacities of DOING pyrolysis machines

3. Pyrolysis machine configurations

The common configurations of pyrolysis machines include pyrolysis reactor, cooling system and tail gas cleaning system. But to enhance the working efficiency and performance, DOING also provides other optional configurations for our customers, such as the auto-feeder to enhance working efficiency, safety device-vacuum device to enhance working safety, and if you have the higher requirements for environmental protection, we also have the desulfurization tower to make further purification of the exhaust gas. Of course, the more perfect configurations, the higher the price.

Some optional configurations for pyrolysis machines

Some optional configurations for pyrolysis machines

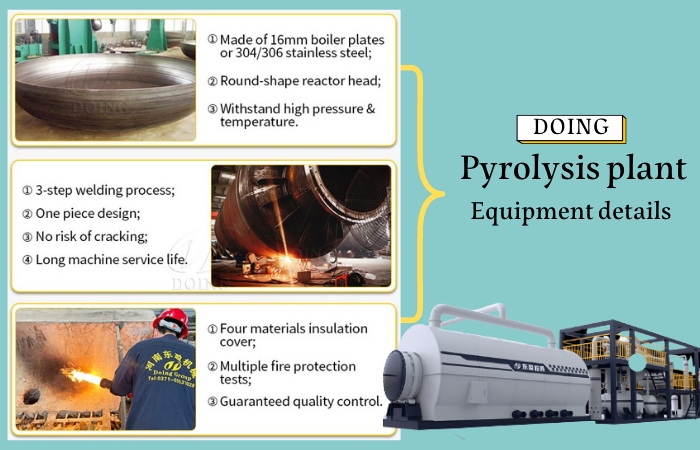

4. Pyrolysis machine adopted materials and technologies

The better the material and technology are, the higher the price, the better the quality. DOING uses high-quality materials in the manufacturing of our pyrolysis machines, ensuring their durability and reliability. For example, when manufacturing the pyrolysis reactor, we use the 16mm boiler plates or 304 stainless steel, which can withstand high temperature and pressure; and our pyrolysis reactor adopts the one-piece design and unique welding method, which can avoid cracking and enhance machine service life. And our pyrolysis machine also has the automatic PLC control technology, which can enhance working efficiency and save labor costs.

Design details of DOING pyrolysis machines

Design details of DOING pyrolysis machines

Apart from the above factors, there are also other factors that will affect the pyrolysis machine price, such as environmental compliance and safety standards, after-sales services, and customization options.

In conclusion, the price of a pyrolysis machine is influenced by several factors, including the type, capacity, configuration, and quality of materials, etc. It's essential to carefully consider these factors when selecting a pyrolysis machine to ensure it aligns with your production needs and budgetary considerations. DOING pyrolysis machines offer competitive prices and reliable performance, making them a popular choice for businesses and entrepreneurs worldwide.

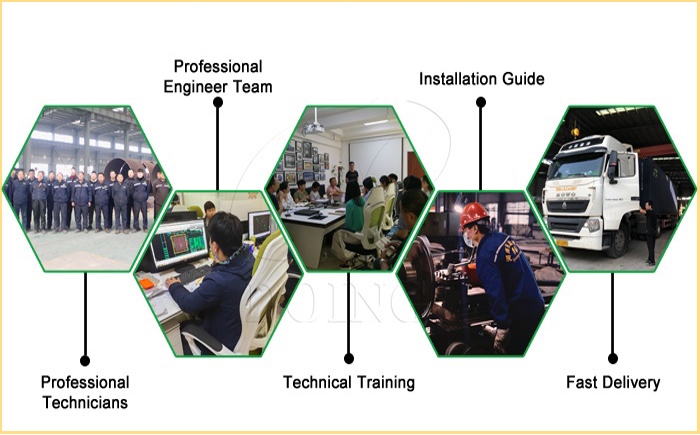

Comprehensive services provided by DOING

Comprehensive services provided by DOING

So if you also want to invest in the pyrolysis machine project, just feel free to contact us, our professional team can provide the detailed scheme for you to ensure your satisfaction. Looking forward to cooperating with you!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.