Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Generally speaking, we can obtain two fuels from plastics with different machines, one is to obtain plastic pyrolysis oil with waste plastic pyrolysis machine, the other is to obtain diesel with waste plastic pyrolysis machine and pyrolysis oil to diesel distillation plant.

Fuel one: Plastic pyrolysis oil

We can turn plastic to plastic pyrolysis oil fuel with the waste plastic pyrolysis machine, which adopts the pyrolysis technology, breaking larger molecules into smaller molecules. In the process of plastic pyrolysis, long chain polymer is broken down into smaller chains of Hydrocarbon Gas and Pyrolysis Oil. Then we can obtain plastic pyrolysis oil from plastics.

1) Brief working process

Feed the waste plastic into the waste plastic pyrolysis machine and heat the reactor to a certain temperature, then the oil gas will come out; after going through the cooling system, the oil gas will cool down to plastic pyrolysis oil;

Various plastics that are suitable for waste plastic pyrolysis machine and their oil yield

Various plastics that are suitable for waste plastic pyrolysis machine and their oil yield

(Pay attention: Not all plastics can be pyrolyzed with waste plastic pyrolysis machine, such as PVC and PET, because PVC contains acid, which can corrode machinery, while PET contains almost no oil. But if these materials are in small quantities, you can mix them with other suitable plastics such as PP, PE, PS, ABS, etc.)

2) Applications of plastic pyrolysis oil

Plastic pyrolysis oil can be used as fuel in various heavy industrial plants such as steel plants, cement plants, boiler plants, power plants, some agricultural equipment, heavy oil generators, etc.

Applications of plastic pyrolysis oil

Applications of plastic pyrolysis oil

Fuel two: Diesel

For further applications, after obtaining plastic pyrolysis oil, we can turn plastic pyrolysis oil to diesel with pyrolysis oil to diesel distillation plant, which adopts catalysts to remove paraffin and gum to obtain good quality diesel.

1) Brief working process

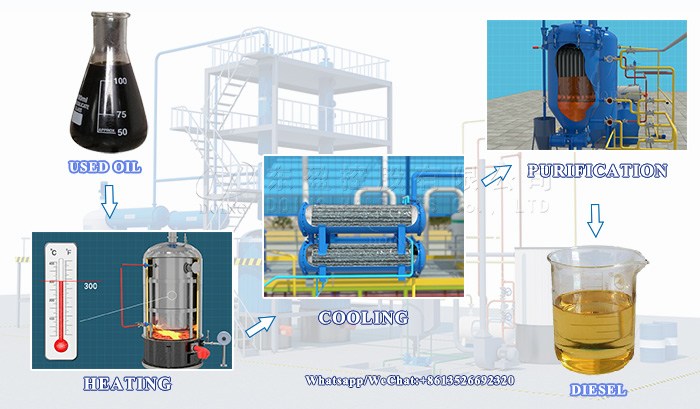

Put plastic pyrolysis oil into the pyrolysis oil to diesel distillation plant and heat the reactor, then the oil gas will come out; after going through the cooling system and catalyst system, we can obtain diesel fuel.

Brife working process of pyrolysis oil to diesel distillation plant

Brife working process of pyrolysis oil to diesel distillation plant

(Pay attention: The obtained diesel is Non-standard diesel. If you want to improve its quality, we also have a purifying system to remove the color and bad smell.)

2) Applications of diesel

Diesel fuel can be used for diesel oil generators, tractors, ships, trucks, heavy oil machinery, boilers, etc.

DOING pyrolysis machine and distillation plant project cases

DOING pyrolysis machine and distillation plant project cases

DOING has been dedicated to the research & development of the green pyrolysis technology of plastic processing for more than 10 years. And DOING pyrolysis machine and distillation plant projects have spread all over the world, such as Brazil, Malaysia, India, Kazakhstan, Mexico, Russia, Colombia, South Africa, etc. If you are interested in turning plastic to fuel or want to learn more information about our pyrolysis machine and distillation plant projects, welcome to contact us!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.