Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Waste plastic pyrolysis plant is a new idea and technology, which can recycle the plastic into useful products: fuel oil, carbon black and syn-gas, which all are very good heating fuels used in industries. In addition, the obtained fuel oil can be further purified to diesel with the waste oil distillation machine to be used in generator, boiler and heavy oil machinery; the obtained carbon black can be refined to make new rubber products and paints.

Multiple uses of obtained useful products

Multiple uses of obtained useful products

Then how to recycle plastic waste into useful products with a waste plastic pyrolysis plant? The general process of recycling plastic waste into useful products includes 3 parts: heating, oil gas cooling and tail gas purifying.

1. Heating processing: Put plastic into pyrolysis reactor through the feeding door. When starting to heat the pyrolysis reactor, it can be heated by fuel oil, gas, wood, coal etc. When the temperature reaches 280-320°C, the oil gas starts to come out. At the same time, the generated combustible gas will be recycled to heat pyrolysis reactor, which can save the cost of fuel materials.

2. Oil gas cooling: After going through the cooling system, the oil gas cools into liquid oil. DOING oil gas cooling system includes two sets of vertical condensers and 2 sets of horizontal condensers, which is the most professional cooling system of industries. Also, it is equipped with a set of oil-water separators and two sets of cooling towers which definitely will ensure all the oil gas to be cooled down during production to improve the oil yield.

DOING Oil gas cooling system

DOING Oil gas cooling system

3. Tail gas purifying: This system includes the Tail gas cleaning system and Desulfurifization tower, which is an environmental protection device to filter the dust and remove some little sulfide contained in the flue gas. One is to purify the combustible gas, the other is to purify the exhausted gas. After purifying, the gas can meet the emission standards in various regions.

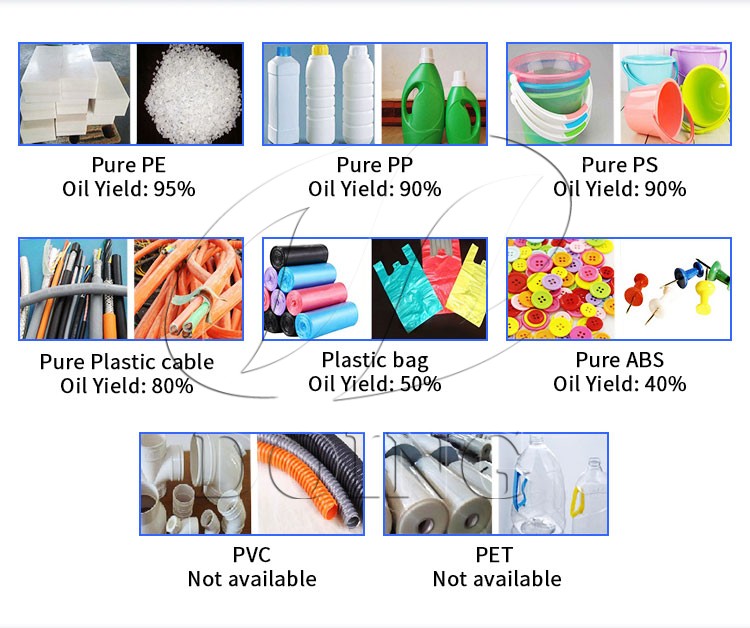

Although the waste plastic pyrolysis plant can recycle plastic waste into useful products, one thing needs to pay attention to: PVC and PET plastics are not suitable for waste plastic pyrolysis plants. If you want to enhance the oil yield, you'd better select high purity plastics with high oil content, such as Pure PP/PE/PS plastics, Pure plastic cable sheath, etc.

Oil yield of various waste plastics that are suitable for pyrolysis plant

Oil yield of various waste plastics that are suitable for pyrolysis plant

Over 13 years, DOING has cooperated with thousands of customers on the waste plastic pyrolysis plant and helped them obtain huge profits. If you are interested in recycling plastic waste into fuel products, welcome to contact us!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.