Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Waste plastic pyrolysis process machine is designed to convert waste plastics to fuel oil, carbon black and syn-gas, whose pyrolysis temperature is lower than 400℃, belonging to low temperature pyrolysis. The pyrolysis reactor is heated outside the furnace, operated by a micro-negative pressure and oxygen-depleted thermal cracking process. The micro-negative pressure process can discharge the gas in time during production to ensure that the gas in the furnace does not leak out and improve the pyrolysis efficiency.

DOING waste plastic pyrolysis process machine

DOING waste plastic pyrolysis process machine

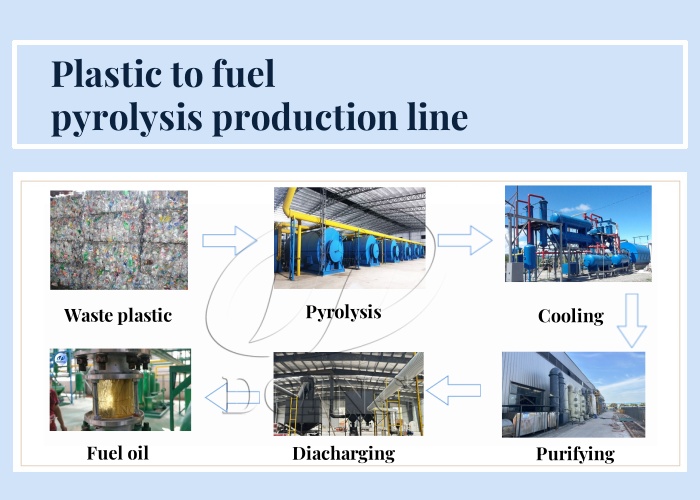

The following is a brief introduction about the step of the waste plastic pyrolysis process machine:

(1) Plastic Feeding: Load waste plastic into pyrolysis reactor with auto-feeder or manually.

(Note: Different types of waste plastic pyrolysis process machine have different requirements about the states of waste plastics, for the semi-continuous and fully continuous type machine, we need to m make pretreatment for waste plastics to small particles.)

(2) Heating and Pyrolysis: After the loading is completed, the plastic cracking process starts. At the initial start-up, wood, coal, fuel oil, natural gas all can be used as the heat source. After heating for 2 hours, oil and gas can be produced stably, and the non-condensable pyrolysis gas can be used as the heat source for the subsequent pyrolysis process after purifying. When the temperature in the pyrolysis furnace reaches 150°C, the pyrolysis process starts. When the temperature reaches 250°C, the pyrolysis reactor rotates and stirs to ensure complete and stable pyrolysis. In the later stage of pyrolysis, the temperature in the furnace rises rapidly, and the pyrolysis activity is stopped at this time.

Work step of waste plastic pyrolysis process machine

Work step of waste plastic pyrolysis process machine

(3) Oil and gas cooling: The generated oil gas is condensed to 70°C, the organic hydrocarbons above C4 are condensed into refined oil, and the oil pump is transported to the oil product warehouse for storage;

(4) Gas Collection and Utilization: The uncondensable gas is directly transported to the pyrolysis furnace and used as the heat source fuel of the subsequent pyrolysis process.

(5) Carbon black treatment: After the pyrolysis process is completed and oil gas is cooling, we can discharge the obtained carbon black. For batch type machines, we need to cool pyrolysis reactor and then discharge carbon black; for semi-continuous and fully continuous machines, we can discharge carbon black in the high temperature.

Environmental protection for waste plastic pyrolysis process machine

Environmental protection for waste plastic pyrolysis process machine

(6) Exhaust gas purifying: After the pyrolysis process is completed, we need to purify the exhaust gas generated with the environmental protection systems based on the emission standards in different countries.

(7) Final products further processing

In some cases, further refining of the obtained fuel oil may be necessary to improve its quality, remove contaminants, and enhance its utility as a diesel fuel with the waste oil distillation machine. And DOING also provides the carbon black deep processing production line to make further utilization of the carbon black.

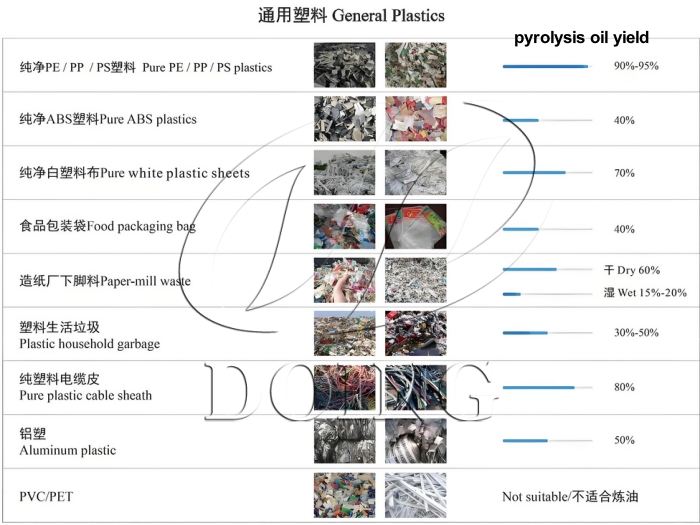

Raw material and oil yields for waste plastic pyrolysis process machine

Raw material and oil yields for waste plastic pyrolysis process machine

Waste plastic pyrolysis process machines can make full utilization of waste plastics and generate huge profits for our customers, and our machine can process various types of waste plastics, such as pure PP/PE/PS/ABS plastics, aluminum plastic, paper mill waste, food package bags, plastic household garbage, medical plastic waste, agricultural plastic film, etc. If you also have plastics to be recycled, just feel free to contact us directly!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.