Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Plastic recycling using pyrolysis machines has emerged as a promising solution to tackle plastic waste while generating significant revenue. The profitability of this process depends on various factors, including raw material costs, operational efficiency, end products, and market demand.

Source of Plastic Waste: The cost of acquiring plastic waste can vary significantly. Sourcing waste locally through municipal waste collection or industrial processes can reduce costs. In some cases, plastic waste can be obtained at no cost, which can greatly enhance profitability.

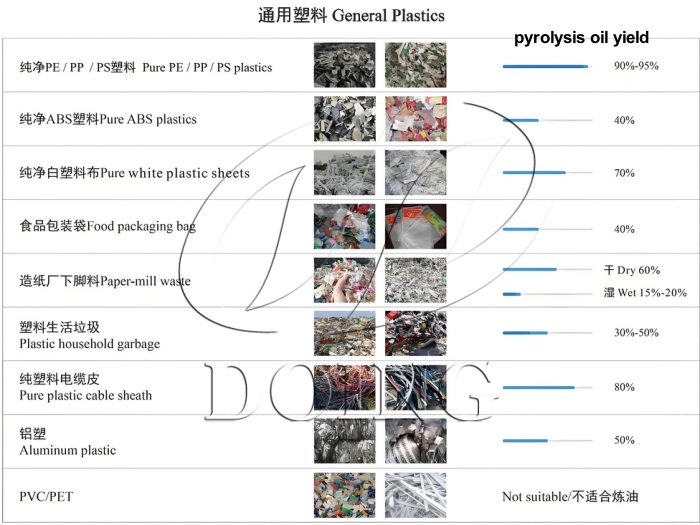

Quality of Plastic: Not all plastics are suitable for pyrolysis. High oil yield plastics such as PE, PP, and PS are ideal. In contrast, PVC and PET are not recommended due to their lower yields and potential environmental concerns.

General plastic pyrolysis oil yield

General plastic pyrolysis oil yield

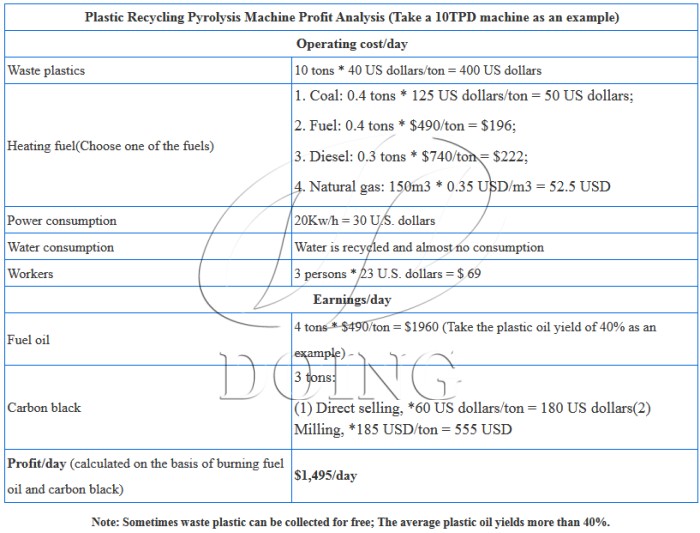

Energy Consumption: Pyrolysis machines require energy to operate, making the cost of electricity or other energy sources a significant factor. Optimizing energy use through efficient machine design and operation can help reduce overall costs. In addition, the Syn-gas generated during the plastic recycling pyrolysis process can be recycled to heat the reactor, saving the overall operating investment cost.

Maintenance and Repairs: Regular maintenance and occasional repairs are essential to keep the machine running efficiently. Investing in high-quality equipment and a reliable maintenance schedule can minimize downtime and repair costs.

Labor Costs: The number of personnel required to operate and manage the process can impact overall costs. Efficient labor management, such as automation and training, can enhance profitability.

Plastic recycling pyrolysis machine profit analysis

Plastic recycling pyrolysis machine profit analysis

Fuels (Pyrolysis Oil): This is the primary product of pyrolysis and can be sold to various industries, including transportation and manufacturing. The market for pyrolysis oil is growing, driven by increasing demand for sustainable fuels. Pyro;ysis oil can also be refined into diesel through waste oil refining machine, so that it has a wider range of uses.

Carbon Black: This valuable byproduct is used in tires, rubber products, and inks, offering additional revenue potential. High-quality carbon black can command premium prices in the market.

Usages of plastic recycling machine outputs

Usages of plastic recycling machine outputs

Local and International Markets: Understanding the demand for end products in both local and international markets is crucial. High demand can drive prices up, increasing profitability. For example, countries with strict environmental regulations are more likely to support the recycling management of waste plastic and the corresponding fuel resource regeneration.

Competition: The presence of other plastic recycling facilities in the area can affect pricing and market share. A competitive edge can be gained through superior product quality or cost efficiency.

Plastic recycling with pyrolysis machines can be highly profitable, especially when key factors such as raw material costs, operational efficiency, market demand, and regulatory compliance are optimized. By focusing on producing high-quality end products like fuels and carbon black, and understanding market dynamics, businesses can maximize their profitability in the plastic recycling industry.

DOING waste plastic recycling pyrolysis machine manufacturer services

DOING waste plastic recycling pyrolysis machine manufacturer services

We, Henan DOING, as a professional machine manufacturer and supplier, are experienced. Our professional business and engineering team work together to to develop professional and exclusive plans for each customer, helping many customers to carry out plastic recycling pyrolysis business. If you also have a corresponding plastic recycling project plan, please contact us.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.