Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Plastic pyrolysis technology can convert waste plastics into fuel oil, carbon black, combustible gas and other resources, bringing considerable benefits. However, there may be some risks in the process of plastic pyrolysis, which need to be understood in advance, mainly including the following three aspects:

Waste plastic to fuel pyrolysis process

Waste plastic to fuel pyrolysis process

1. Safety risk: flammable gas may be produced during the pyrolysis process, which may lead to explosion or fire accidents if improper operation or equipment failure.

2. Environmental pollution: Harmful gases may be released during the pyrolysis process, such as incompletely burned hydrocarbons, sulfides and other gases. If not handled properly, it will cause serious pollution to the environment.

3. Equipment coking and carbon deposits: Waste plastics have complex composition and uneven pyrolysis may form coking and carbon deposits in the furnace, affecting the efficiency and life of the equipment.

In order to avoid the above risks of plastic pyrolysis, the following measures can be taken:

• Strictly control the process parameters: ensure that the pyrolysis temperature, pressure and reaction time are within safe and effective ranges to avoid the generation of excessive non-condensable gases and harmful substances.

• Use high-quality pyrolysis equipment: Choose waste plastic pyrolysis equipment provided by qualified and reputable manufacturers to ensure that the equipment is reasonably designed and the materials are resistant to high temperatures and corrosion to reduce safety hazards.

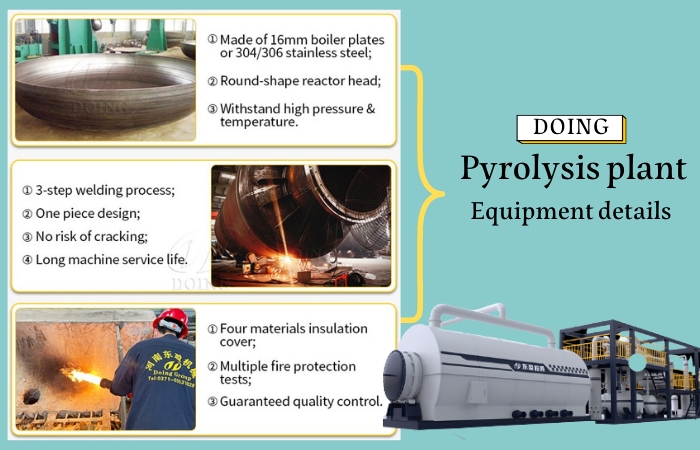

High quality plastic pyrolysis equipment design details

High quality plastic pyrolysis equipment design details

• Use advanced pyrolysis technology: Find a waste plastic to fuel oil pyrolysis process with a mature project operation site, which can effectively balance pyrolysis and be equipped with anti-coking devices.

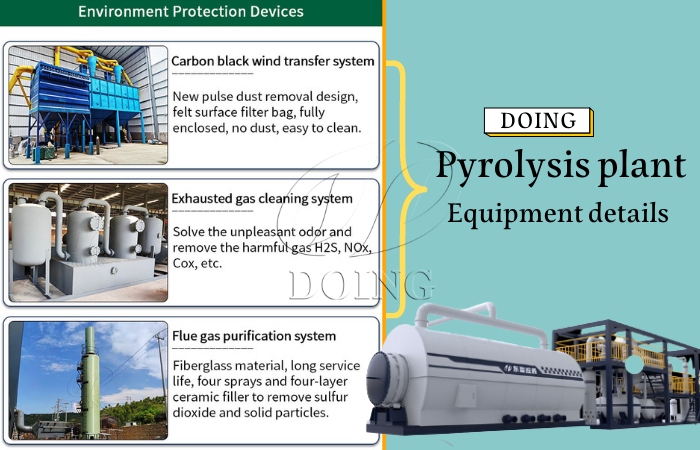

• Install environmental protection treatment facilities: Equip with efficient flue gas purification systems (such as spray towers, filters, etc.) and wastewater treatment systems to ensure that emissions comply with environmental standards.

Environmental waste plastic pyrolysis equipment for sale

Environmental waste plastic pyrolysis equipment for sale

• Regular maintenance and inspection: Regular maintenance and inspection of waste plastic pyrolysis equipment, timely cleaning of coking and carbon deposits, to ensure equipment operating efficiency and safety.

• Centralized control and intelligent management: Implement a central monitoring system to monitor various indicators in the pyrolysis process in real time, adjust process parameters in a timely manner, and prevent safety accidents.

PLC system of Waste plastic pyrolysis equipment

PLC system of Waste plastic pyrolysis equipment

• Compliance operation and personnel training: Ensure that operators have received professional training and are familiar with equipment operating procedures and emergency response procedures to improve the overall safety management level.

In summary, through scientific management and technological upgrading, the risks of plastic pyrolysis can be effectively reduced, making it a more environmentally friendly and safer way to treat waste plastics. Henan Doing Company has focused on the research, development and improvement of pyrolysis equipment for 14 years. The equipment is sold in more than 100 countries and regions and is widely praised by customers. Welcome to contact us to obtain professional and high-quality plastic pyrolysis equipment related content.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.