Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

After deciding to purchase plastic for an oil pyrolysis plant and carrying out the project, selecting the suitable size of the project site foundation and making reasonable planning have become an important issue for most customers. Next is a brief introduction about this:

Commonly, the size of the foundation required for a plastic to oil pyrolysis plant depends on several factors such as the capacity of the plant, the equipment dimensions, material and final products storage and the structural requirements for stability and safety.

1. Plant Capacity: Plastic to oil pyrolysis plants come in various sizes, typically handling anywhere from a few tons to hundreds of tons of plastic waste per day. Take the popular type-15TPD plastic to oil pyrolysis plant as an example, the reactor foundation's maximum width would be approximately 10 meters, and the longest part would measure around 11 meters. Obviously, the larger the capacity of the plastic to oil pyrolysis plant, the bigger the foundation size.

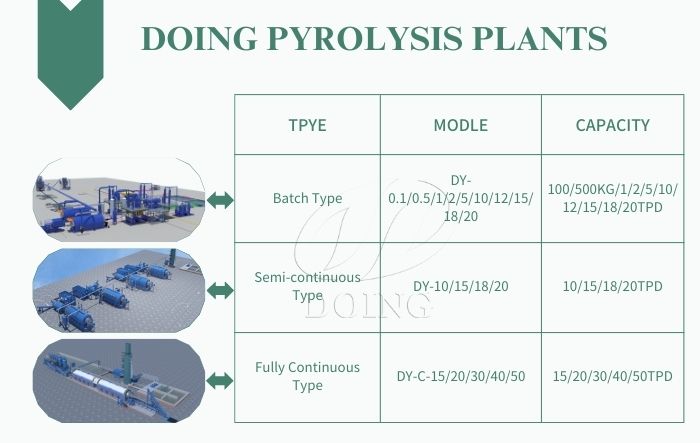

Types and processing capacities of DOING plastic to oil pyrolysis plant

Types and processing capacities of DOING plastic to oil pyrolysis plant

2. Selected equipment components: The whole plastic to oil pyrolysis plant consists of pyrolysis reactor, cooling system, environmental protection systems and other auxiliary equipment, which significantly impacts the foundation footprint. You'll need precise dimensions of each piece of equipment and the necessary spacing between them for operation and maintenance. And the same part will also have different designs depending on the type of plastic to oil pyrolysis plant. Take the cooling system as an example, we have two designs: horizontal&vertical condensers and water tank cooling system, which have different sizes influence the whole foundation size of the plastic to oil pyrolysis plant project.

Optional equipment for DOING plastic to oil pyrolysis plant

Optional equipment for DOING plastic to oil pyrolysis plant

In addition, some customers will also select other optional equipment like environmental protection system to meet local environmental standards and safety devices to ensure work safety. Of course, the more complete the equipment selection, the larger the project foundation size.

3. Safety and Access: Adequate space around the plastic to oil pyrolysis plant for safety zones, emergency egress, and access for maintenance should also be factored into the foundation design. To get a specific dimension, consult with a professional engineer or the manufacturer of the plastic to oil pyrolysis plant you are considering. They will provide detailed blueprints and specifications based on your plant's capacity and the specific equipment configuration, ensuring compliance with local building codes and safety standards. Without these specifics, it's not possible to provide an exact foundation size, but typically, foundations for such plants can range from hundreds to thousands of square feet.

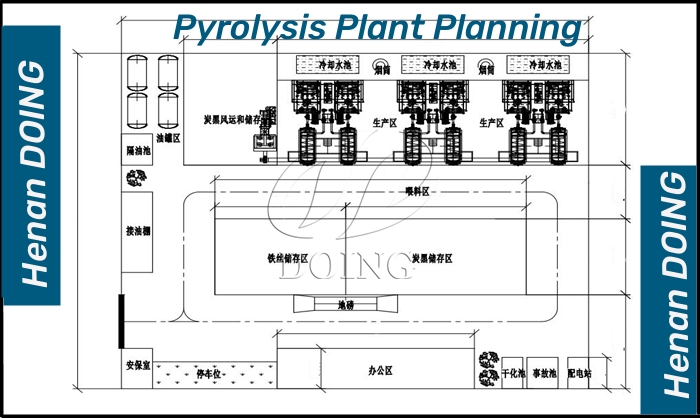

Pyrolysis plant site planning provided by DOING

Pyrolysis plant site planning provided by DOING

Additionally, we also need to set aside enough space for plastic waste and final products(plastic pyrolysis oil and carbon black) storage.

All in all, the size foundation for holding pyrolysis to oil pyrolysis plant is affected by many factors. And if you also want to invest in the plastic to oil pyrolysis plant project, welcome to contact us and send your requirements to us, our sales manager can customize a suitable plan an factory plan drawing based on your location and actual situation.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.