Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

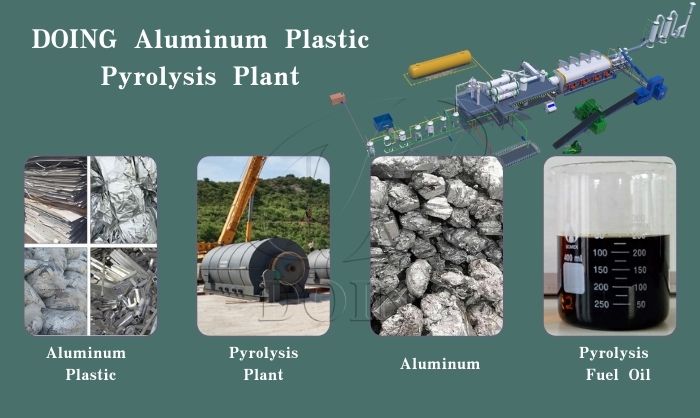

China's popular aluminum plastic recycling machines---pyrolysis equipment are based on pyrolysis technology, designed to separate aluminum from composite materials such as aluminum-plastic packaging, medical blister packaging and cable waste, and can also obtain plastic pyrolysis products such as pyrolysis oil, carbon black and syngas.

Aluminum plastic pyrolysis process

The reason why pyrolysis equipment became a popular aluminum plastic recycling technology in China lies in it breaks through the limitations of the original crushing and sorting type aluminum-plastic recycling machine and can be used to process a variety of waste aluminum-plastic raw materials, even aluminum-plastic composite materials that are glued together. By understanding the working principle, key features and benefits of the DOING’s aluminum-plastic recycling pyrolysis equipment, you can make an informed decision about integrating this technology into your waste management.

Feeding: Aluminum plastic composite materials, such as packaging waste and medical blister packs, are fed into the pyrolysis reactor. These materials usually consist of a thin aluminum foil layer bonded to plastic.

Pyrolysis: The reactor is heated to 300–450°C in an oxygen-free environment. The plastic component undergoes thermal decomposition, breaking down into hydrocarbon vapors (pyrolysis oil and gas), while the aluminum remains intact.

Separation: The vaporized hydrocarbons are condensed into pyrolysis oil, which can be used as fuel. The aluminum is separated as a solid residue, clean and free from plastic.

Gas Recycling: Non-condensable gases (syngas) are recycled to heat the reactor, making the process energy-efficient.

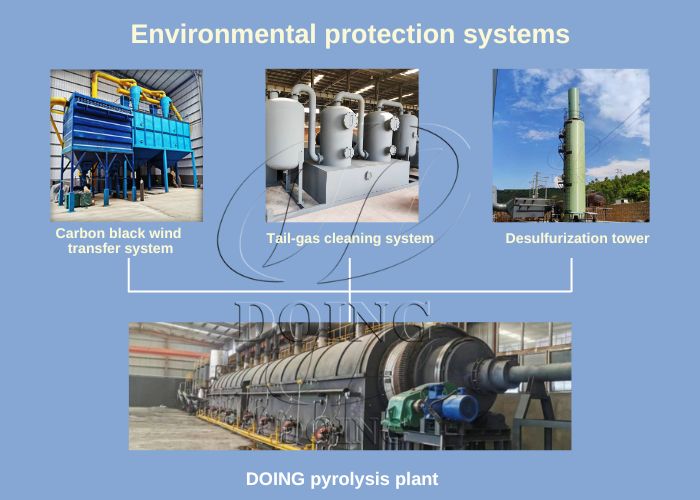

Emission Control: Advanced machines like exhaust purification system to treat exhaust gases, ensuring compliance with environmental standards.

The DOING pyrolysis equipment stands out as a new and popular aluminum plastic recycling machine in China for several reasons:

High Recovery Rate

The machine can efficiently separate aluminum with up to 99% purity and recover a high proportion of plastic, maximizing resource utilization and economic returns.

Eco-Friendly

The machine is designed with minimal emissions and waste. Advanced emission control and dust collection systems ensure that exhaust gases are treated properly, meeting strict environmental standards and reducing pollution.

DOING aluminum plastic pyrolysis equipment environmental protection devices

Versatile

It can handle various types of aluminum plastic composites, including packaging materials, medical waste, and cable waste, making it suitable for different recycling scenarios.

Aluminum plastic pyrolysis equipment raw materials

Cost-Effective and Energy-Efficient

The recycling of syngas to heat the reactor significantly reduces energy consumption. The conversion of waste into valuable resources like aluminum and pyrolysis oil also brings substantial economic benefits.

This pyrolysis technology is widely adopted in China due to its efficiency and environmental benefits. It is very suitable for recycling companies or institutions that need to recycle and process waste aluminum and plastic materials in large quantities, especially companies that want to maximize recycling benefits when the types of aluminum and plastic materials are complex. According to feedback from our Chinese customers, the efficiency of recycling aluminum plastic materials using pyrolysis equipment is extremely high, saving a lot of raw material sorting costs.

DOING aluminum plastic pyrolysis equipment manufacturer

DOING Company, as a professional manufacturer of waste recycling pyrolysis equipment in China, has rich experience and technical strength. We are committed to providing high-quality, reliable equipment and comprehensive after-sales service. Our team of experts can offer customized efficient and environmentally friendly aluminum plastic pyrolysis equipment based on your specific needs, ensuring the smooth operation of your recycling business.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.