Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Plastic is a derivative of petrochemicals and contains paraffin substances. In the plastics pyrolysis process, it is inevitable to encounter the situation of producing wax oil. Wax oil is usually a viscous liquid with a relatively high boiling point range. It may have a yellowish to brownish color. Below are the key reasons why wax oil is generated during the plastic pyrolysis process analyzed by DOING :

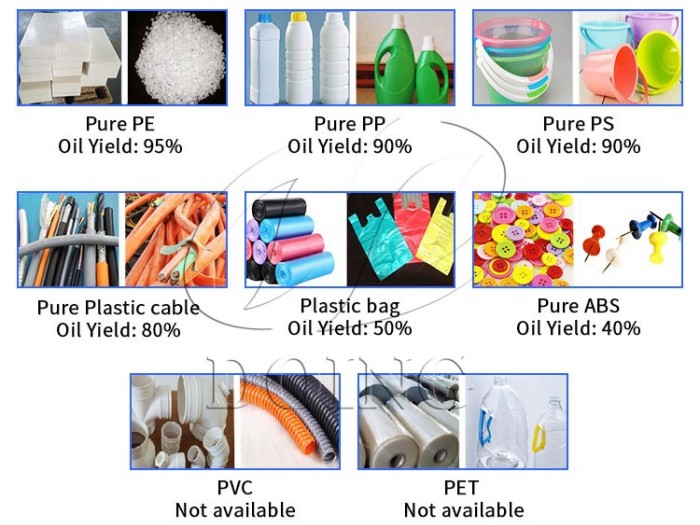

1. Type and Composition of Plastics.

Different types of plastics (such as polyethylene PE, polypropylene PP, etc.) contain hydrocarbon chains of varying lengths. When these plastics are heated in an oxygen-free environment, they break down into smaller molecules. For plastics with longer carbon chains, the decomposition products may include relatively large but still light hydrocarbon compounds, which form the main components of wax oil.

DOING plastic pyrolysis technology

DOING plastic pyrolysis technology

2. Pyrolysis Temperature.

The choice of pyrolysis temperature significantly affects the distribution of the final products. Lower pyrolysis temperatures (approximately 400°C to 500°C) of plastic pyrolysis machine tend to produce more liquid products, including wax oil. This is because, at these temperatures, the breakdown of long-chain hydrocarbons is incomplete, resulting in heavier hydrocarbons that condense into wax-like substances.

3. Residence Time.

The residence time of the material in the reactor also plays a role. Shorter residence times may lead to incomplete cracking of the hydrocarbons, leaving behind larger molecules that contribute to the formation of wax oil.

4. Condensation Process.

During the cooling and condensation phase, some of the volatile hydrocarbons condense into liquid form. Heavier hydrocarbons that do not fully evaporate or crack remain as viscous liquids, contributing to the formation of wax oil.

Condensation system of DOING plastic pyrolysis machine

Condensation system of DOING plastic pyrolysis machine

To reduce or remove the production of wax oil and improve the yield of more valuable products, DOING designs the following measures:

1. Increase Pyrolysis Temperature

Operating at higher temperatures promotes further cracking of hydrocarbons, reducing the formation of wax oil.

2. Pre-Treat Feedstock

Using clean, sorted, and homogeneous plastic feedstock can lead to more predictable and desirable product distributions.

The oil yield of different plastics

The oil yield of different plastics

3. Design a special condensation pipe

Enlarging and thicken it to prevent condensation pipe blockage

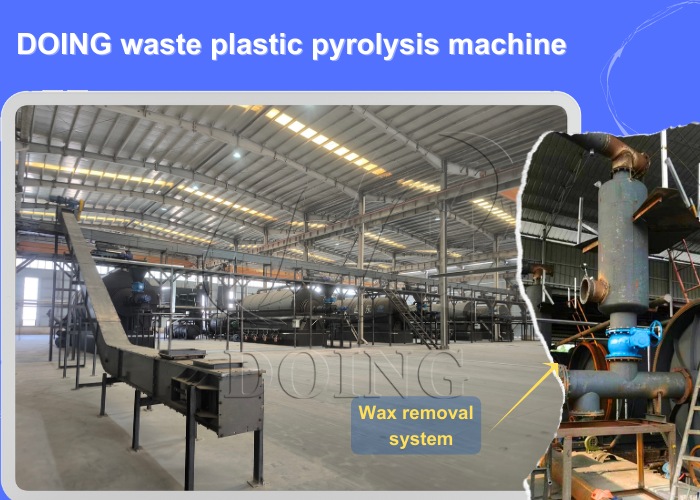

4. Add a wax reduction device

Adding a wax reduction device to the inner wall of the main plastic pyrolysis furnace, and add a heat conduction coil outside the crude oil temporary storage tank to prevent the plastic oil from solidifying and waxing after the temperature drops.

DOING wax reduction device

DOING wax reduction device

In conclusion, the generation of wax oil in the plastic pyrolysis process is a complex phenomenon influenced by multiple factors. However, with DOING innovative waste recycling pyrolysis machine, the challenges associated with wax oil production can be effectively addressed. Choosing DOING is your ideal choice for you to set up a plastic recycling pyrolysis plants.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.