Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

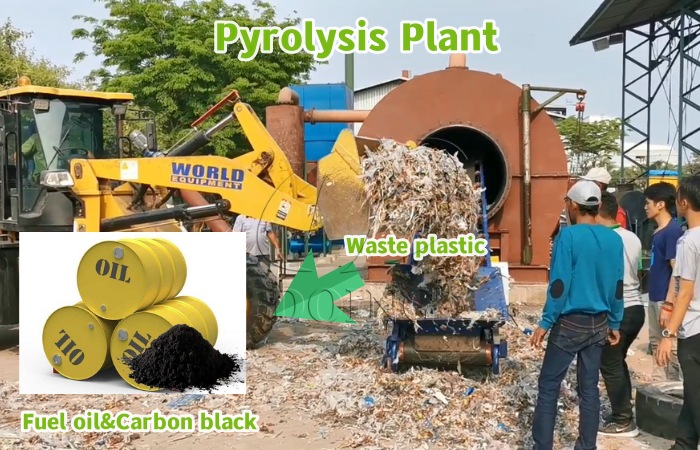

Waste plastic oiling system, also called waste plastic pyrolysis plant, which can convert waste plastics to useful products, such as fuel oil, carbon black and combustible gas in an environmentally friendly method.

DOING waste plastic oiling system for sale

DOING waste plastic oiling system for sale

The cost of DOING waste plastic oiling system varies from its types, capacities, designs and configurations, etc., with the common price range of 11000 dollars to 1000000+ dollars. Of course, the better the designs and technologies, the better the quality, the higher the price.

So if you want to invest in the waste plastic oiling system, here DOING can provide some tips to guide you and get the right waste plastic oiling system with good cost performance.

Firstly, purchase the waste plastic oiling system directly from a professional manufacturer rather than a trading company or the third party if your company can do the importing, thus you can save a lot of agency fees. DOING Group is a good choice for you, who is a professional waste plastic oiling system manufacturer with abundant experience. During the discussing process, our team can customize the suitable exporting and shipping scheme based on your actual situation.

One project display of DOING waste plastic oiling system

One project display of DOING waste plastic oiling system

Secondly, pay attention to the technological process of the waste plastic oiling system. Normally, better technology always means higher cost. But it will finally prove that a waste plastic oiling system with the best technology is also the most cost-saving one, because it can help you avoid many problems. For example, the DOING waste plastic oiling system adopts the latest technology and best material to manufacture the pyrolysis reactor, which can withstand high temperature and pressure to enhance machine service life, saving on repair and replacement costs; and our waste plastic oiling system is equipped with environmental protection systems, which can meet the emission standards in various regions to help our customers pass environmental impact assessment procedures as soon as possible to reduce some unnecessary costs.

Environmental protection systems of DOING waste plastic oiling system

Environmental protection systems of DOING waste plastic oiling system

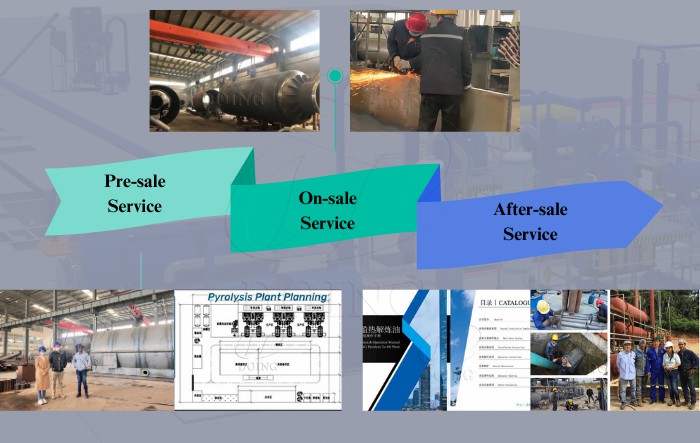

Thirdly, consider the overall strength of the waste plastic oiling system manufacturer and supplier. A good waste plastic oiling system manufacturer should have a strong technical and R&D team to keep upgrading the technology, and have rich production experience as well as a professional sales and after-sales team to guarantee good customer service. And cooperating with the waste plastic oiling system manufacturer with strong overall strength, you can complete investment projects faster and better without worrying about any question from suitable machine selection, shipping, to installation and maintenance.

Comprehensive services provided by DOING

Comprehensive services provided by DOING

Over the past 13 years, DOING has cooperated with many customers in various regions on our waste plastic oiling systems and received lots of good feedback. And we also have passed the certificates such as SGS, CE, ISO to ensure the good quality of our waste plastic oiling system, so if you are interested in our waste plastic oiling system, just tell us your actual demands, such as the machine types and capacities you wanted, we can provide the detailed price scheme for you.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.