Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

According to statistics, there are more than 300 types of plastics, with various types and different performances and uses. Although various plastics have great differences in performance, they can all be recycled. The recycling technologies of waste plastics mainly include the following types:

(1) Heat energy recovery. This is the easiest way to recycle, which is to burn the plastic and use the heat energy it produces. Municipal waste-to-energy plants are one such example. Although the heat generated by the burning of plastic waste can be used to generate electricity, it also produces toxic gases, so the generated gases need to be treated before they can be discharged.

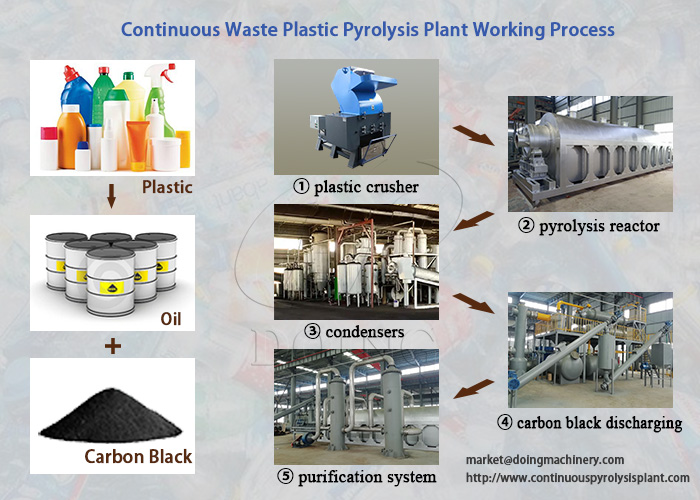

(2) Converted to fuel oil. Many types of waste plastics, such as PE, PP, PS, ABS, paper mill waste and other plastics, can be converted into low-molecular-weight olefin fuels through high-temperature pyrolysis by pyrolysis plant. The plastic pyrolysis fuel oil can be further used for generator power generation, boiler heating or heating and so on. It can also be further processed into diesel oil for diesel generators, heavy machinery, etc. through pyrolysis oil distillation plant.

Waste plastic pyrolysis plant and its working process

Waste plastic pyrolysis plant and its working process

(1) Hot melt recycling technology. PET bottles can be recycled into PET products through hot melt recycling. Common plastic varieties, such as HDPE, PP, etc., can be regenerated by hot melting after mixing, and can also be remade into plastic daily necessities such as buckets and shoe heels that do not require high quality.

(2)Waste plastic blending modification recycling technology. It is a technology that mixes waste plastics with other materials to improve the performance of other materials and remake them into new products. For example, park plank roads, fences, etc. are made by mixing waste plastics with wood.

(3) Chemical modification and recycling technology of waste plastics. Chemical methods can be used to convert waste plastics into other useful materials with high added value, such as coatings, adhesives, industrial water absorbents, ion adsorbents, etc.

The project cases of pyrolysis plant installed by DOING Group

The project cases of pyrolysis plant installed by DOING Group

Among them, the project of using pyrolysis plant to recycle waste plastics into fuel oil is very popular due to its advantages of environmental protection, waste reduction and resource utilization. For more questions about investment prospects and profit analysis of waste plastic pyrolysis recycling projects, and pyrolysis plant prices, please leave a message, or send an email or WhatsApp for consultation. Henan Doing Company will provide you with all-round services.

Releate article:

Copyright © 2015-2026.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.