Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Pyrolysis plant, a profitable waste woven bags recycling machine, can be a valuable solution for converting waste woven bags into useful products. Waste woven bags, often made from polypropylene, a kind of plastic with high oil content.

Waste woven bags for pyrolysis plant

Waste woven bags for pyrolysis plant

Generally, we can obtain about 60% fuel oil, 30% carbon black and 10% syn-gas from waste woven bags with the pyrolysis plant, which all have wide applications to generate huge profits for our customers:

Fuel oil can be used as fuel energy in cement factories, steel factories, glass factories, brick factories, boiler heating, heavy oil generators or be refined to diesel oil; carbon black can be used as the heating fuel, which has a higher calorific value than the common coal fuel, and it also can be further refined to make paints or new rubber products; syn-gas can be used as heating fuel for the pyrolysis plant to save the operation cost.

Applications for obtained fuel oil and carbon black

Applications for obtained fuel oil and carbon black

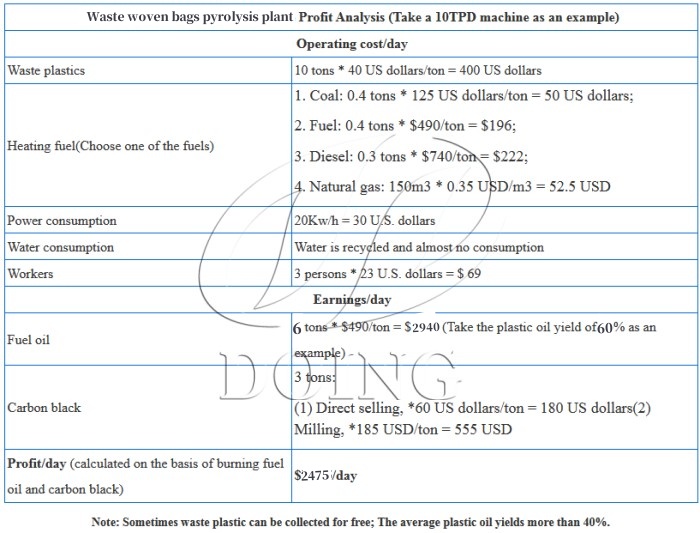

The following is a brief profit analysis of the waste woven bags pyrolysis plant(Take the 10TPD pyrolysis plant as an example):

(Note: the above analysis is based on DOING market survey and real feedback from DOING customers, and the real profit changes with the vary of market.)

Profit analysis of waste woven bags pyrolysis plant

Profit analysis of waste woven bags pyrolysis plant

Now you must have had a clear understanding of the profitability of the waste woven bags recycling machine-pyrolysis plant, then let us have a brief learning of the process of recycling waste woven bags into useful products:

1. Preparation: Clean the dirt, sand or other waste from waste woven bags, and if need, shred the waste woven bags into small pieces, which can enhance the pyrolysis efficiency and avoid wear for the pyrolysis plant;

2. Heat and Pyrolysis: Put the waste woven bags into the pyrolysis plant and the reactor will be heated to a high temperature (typically between 400°C and 600°C) in an inert atmosphere (often nitrogen or steam) to prevent combustion. The pyrolysis causes the waste woven bags to break down into oil gas.

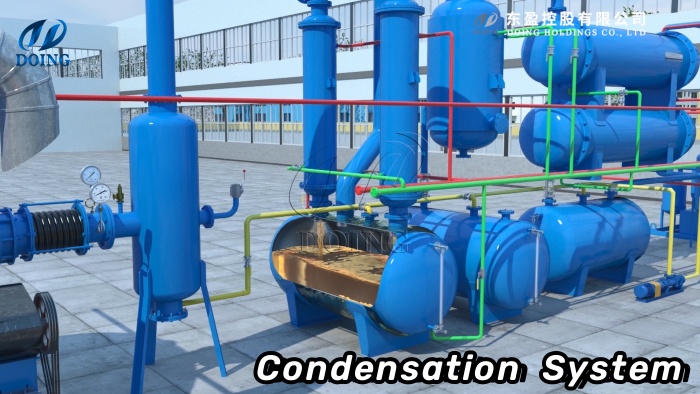

Cooling system for DOING waste woven bags pyrolysis plant

Cooling system for DOING waste woven bags pyrolysis plant

3. Oil gas cooling: Cool the oil gas with the cooling system, then we obtain the main product from the pyrolysis plant-fuel oil;

4. Exhaust gas purifying: The generated syn-gas will be purified with the tail-gas cleaning system to be used as heating fuel for pyrolysis reactor. After pyrolysis heating, the exhaust gas will go through the desulfurization tower to meet the emission standards for discharge;

Desulfurization tower for DOING pyrolysis plant

Desulfurization tower for DOING pyrolysis plant

5. Final products discharge: Finally, we can discharge the obtained products of fuel oil and carbon black from pyrolysis plant.

In a word, pyrolysis plant for recycling waste woven bags can be a profitable venture that addresses both environmental and economic concerns. And in addition to the waste woven bags, there are also other waste that can be recycled with the pyrolysis plant, such as household waste, medical waste, construction waste, etc. If you are interested in our pyrolysis plant, welcome to send your enquiry to us!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.