Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

At present, the common waste plastic treatment solutions on the market are mostly concentrated on gasification and pyrolysis, which are both thermochemical processes used to convert plastic waste into useful products, but they differ significantly in their operating conditions, outputs, and applications:

1. Operating conditions

Gasification involves reacting plastic waste with a controlled amount of oxygen and/or steam at high temperatures (700°C to 1200°C). While pyrolysis occurs in the absence of oxygen, typically at temperatures ranging from 300°C to 600°C.

Difference between plastic pyrolysis and gasification

Difference between plastic pyrolysis and gasification

2. Differences in products.

The products of gasification include combustible gases(the main product), tar and inorganic residues. During gasification process, due to the presence of a certain amount of oxygen, part of plastics will be oxidized, will produce inorganic residue; The products of pyrolysis include fuel oil(the main product), carbon black and combustible gas. Because there is no oxygen involved in the pyrolysis process, so there will not be inorganic residue.

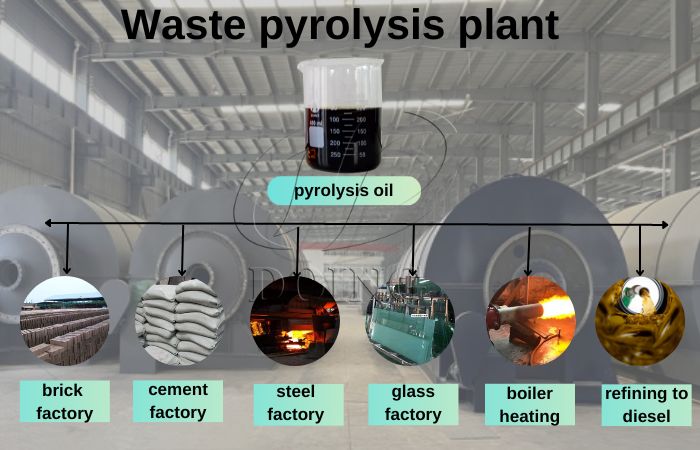

The obtained fuel oil from plastic pyrolysis has the good quality, which can be used in heavy oil machinery, cement plant, steel plant, glass plant, boiler heating or be refined into diesel to enlarge its applications and generate more profits for customers.

Applications of obtained fuel oil from plastic pyrolysis

Applications of obtained fuel oil from plastic pyrolysis

In addition, gasification technology also involves the pretreatment of solid waste, the control of oxygen supply during the gasification process, and the design and operation of the gasifier to ensure efficient and environmentally friendly waste treatment. Compared with plastic gasification, pyrolysis technology is easier to realize ideal effect, and the secondary pollution generated in the process of plastic pyrolysis is smaller, and DOING can equip plastic pyrolysis plants with environmental protection devices of different configurations to meet various environmental protection requirements in different regions. And our plastic pyrolysis plants have cooperated with many countries and receive lots of good feedback, even in some countries, like Poland, Colombia, Switzerland, which have higher requirements for environmental protection.

Projects display of DOING pyrolysis plants

Projects display of DOING pyrolysis plants

In summary, there is a clear difference between the gasification and pyrolysis of plastics in operating conditions and the obtained products. You can select the suitable plastic recycling solution based on your requirements. And if you want to know more details about the waste plastic pyrolysis plant, just feel free to contact Henan DOING Company, our sales manager can provide a comprehensive introduction for you to help you customize the suitable machine scheme. Looking forward to your inquiry!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.