Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

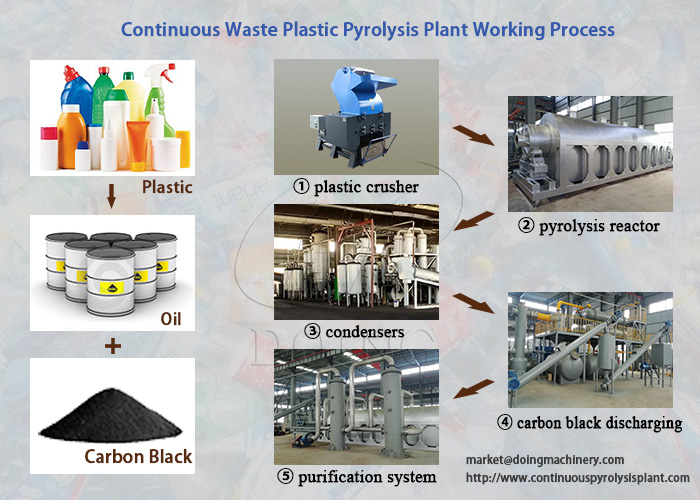

In recent years, the application of plastic products in various fields has become increasingly widespread. It is undeniable that the emergence of plastic products has brought many conveniences to our lives. However, the disposal of waste plastics has become a major headache. With the advancement of technology in recent years,using waste plastic pyrolysis plant to dispose of waste plastics has become a popular method. Next, let's analyze why waste plastic pyrolysis plant is so popular.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

1.Waste plastic pyrolysis plant is environment-friendly.

The new generation of environment-friendly waste plastic pyrolysis plant produced by Doing Group is specially designed to pyrolyze waste plastics. The whole pyrolysis reaction is fully enclosed, no dust or harmful gas is discharged. The tail gas and smoke generated in the process of pyrolysis reaction can be purified by tail gas and smoke cleaning system, then can be discharged without causing secondary pollution to the environment. The waste plastic pyrolysis plant produced by Doing Group has passed the European and American environmental standards and we have installed machines in more than 40 countries around the world.

Tail and smoke cleaning system

Tail and smoke cleaning system

2.Application of end products of waste plastic pyrolysis plant are widely used.

After the waste plastic is processed by the waste plastic pyrolysis plant, fuel oil, non-condensable gas and carbon black can be obtained. These end products can be widely used in many industries and bring great profits to customers. For example, fuel oil is a good heating fuel can be used in cement factory, boiler heating, steel factory,etc. Fuel oil can also be refined by waste oil distillation machine to diesel, which can have higher business value. Carbon black could be made into pellets for burning and heating, just like coal, or refining foe making new rubber products. The price of fuel oil and carbon black has been rising, and its market prospects are very good.

Pyrolysis oil application

Pyrolysis oil application

Carbon black application

Carbon black application

3.Waste plastic pyrolysis plant is easy to operate.

The continuous waste plastic pyrolysis plant adopts PLC control system, which has a high degree of automation. A single production line needs 1-2 people, which not only is easy for people to operate, but also saves manpower.The main advantage is it has continuous feeding and slagging system, which greatly improves the production efficiency.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant not only enables waste plastic get effective recycling, turning waste into treasure, but also protects the environment. If you want to know more information about waste platic pyrolysis plant, please contact us.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.