Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Plastic waste is one of the most common pollutants on the earth, and as environmental awareness grows, countries are paying more and more attention to recycling plastic waste. Waste plastic to oil plant can convert waste plastic into fuel oil, which is one of the best ways to recycle plastic at present. But many people still have a lot of questions about Doing waste plastic to oil plant, so we have compiled five questions that customers often ask, hoping to help people who want to engage in this industry.

Frequently asked questions and answers of waste plastic to oil plant

Frequently asked questions and answers of waste plastic to oil plant

Q1: What kind of raw materials can be processed by Doing waste plastic to oil plant?

A: Waste plastics that can be processed mainly include PP, PE, PS, PET, nylon, foam, plastic film, and other plastic products. But PVC plastics cannot be processed because hydrogen chloride will be produced when pyrolyzing, which will corrode the pyrolysis plant. In addition, Doing waste plastic to oil plant can also process rubber products, such as car tires, truck tires and other vehicle tires, cable skins, and all-rubber products.

Q2: How long is the processing time of Doing waste plastic to oil plant?

A: The process of a batch of waste plastic includes three parts: feeding, pyrolysis and discharging. Depending on the capacity of the equipment, the processing time varies. If you install a waste plastic to oil plant with a daily capacity of 1t, the process time will be about 7-8 hours, if you install a waste plastic to oil plant with a daily capacity of 12t, the process time will be about 20-22 hours.

Q3: How many workers are needed to operate Doing waste plastic to oil plant?

A: You need to hire about 3-4 workers to operate this equipment. The most important worker is the worker who controls the fire. The temperature depends on the fire, and the temperature is the key to pyrolysis. The oil and gas will be produced only at the most suitable temperature.

Q4:Does Doing waste plastic to oil plant pollute the environment?

A: Because Doing waste plastic to oil plant is equipped with high quality environmental protection equipment, it will not pollute the environment. Pollution mainly includes 4 aspects: waste water, waste gas, waste residue and noise. For these aspects, Doing waste plastic to oil plant has designed the corresponding environmental protection equipment.

1. Waste water: one part is condenser water, another part is dust removal water, which is circulating water, only evaporation.

Exhaust gas and waste slag discharging system

Exhaust gas and waste slag discharging system

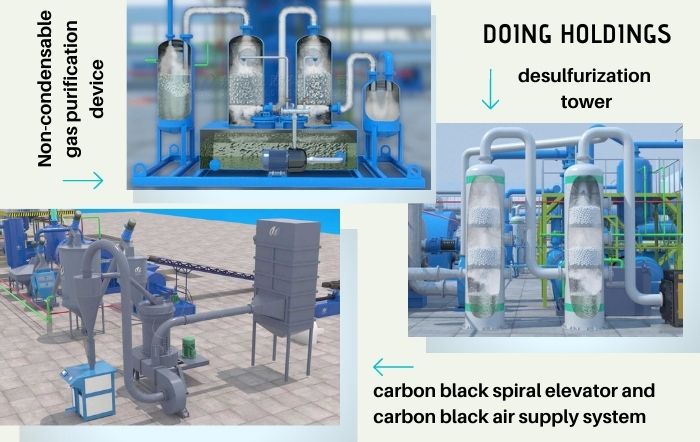

2. Exhaust gas: one is combustible gas that cannot be cooled into oil. We also call it as non-condensable gas. Its main component is C1-C4 alcohol, which is methyl ethylene propylene. It is a good fuel, but it also contains some hydrogen sulfide gas. With our deodorization system, a clean non-condensable gas can be obtained. The other is the flue gas produced by pyrolysis reactor heating. The pyrolysis reactor is equipped with a professional desulfurization tower for desulfurization treatment, after which the remaining water vapor is discharged through the chimney, which meets the environmental protection requirements.

3. Waste slag: The waste slag is mainly generated when feeding raw materials and discharging carbon black. The whole operation of Doing waste plastic to oil plant is sealed to ensure no waste slag leakage.

4. Noise treatment: Doing waste plastic to oil plant uses low noise fan, the noise is less than 60 decibels, and the noise of power is less than 50 decibels.

Q5: What are the safety measures of Doing waste plastic to oil plant?

A: Doing waste plastic to oil plant operates near zero pressure. To further ensure the stable operation of the waste plastic to oil plant, we have designed the following safety equipment.

1. Two pressure valves and an alarm bell: The pressure valve is set with a pressure value of 0.3-0.4MPa. When the pressure value reaches this value, an alarm bell will sound. If there is no worker on duty, the pressure valve will open automatically and release the pressure in the reactor.

2. Oil-water separation device and water seal device: They work on the same principle. There is water in the devices and the oil gas pipe is under the water surface. Due to the water pressure, oil gas cannot return to the reactor, which can prevent oil gas back-flow and avoid explosion.

3. Vacuum device: It can ensure the equipment is operated under negative pressure, avoiding the danger of high pressure inside the equipment.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.