Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

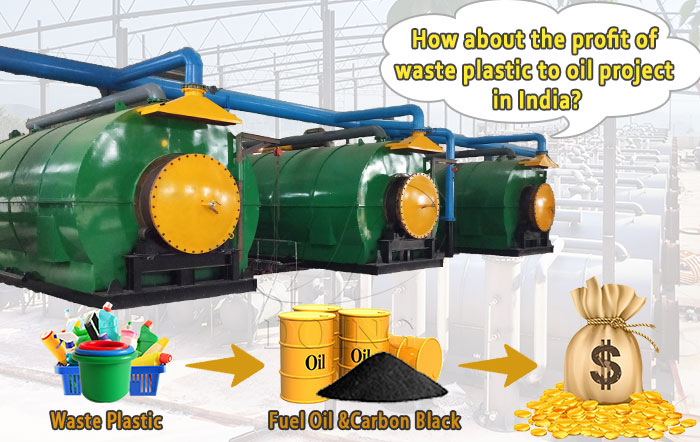

Many Indians know that waste plastic to oil plant can convert waste plastics into pyrolysis oil, carbon black and combustible gas, so they want to invest in waste plastic to oil project. Since waste plastic resources are easily available in India and local oil prices are high, they believe it is a profitable project. Can a waste plastic to oil project really work in India? How about the profit? Let's take a project with 10 TPD waste plastic to oil plant as an example and analyze the costs and revenue of this project.

How about the profit of waste plastic to oil project in India?

How about the profit of waste plastic to oil project in India?

◆ Costs of waste plastic to oil project

The cost of the waste plastic to oil project mainly includes raw materials, electricity, fuel and labors. The pyrolysis oil produced by the waste plastic to oil plant can be used directly as fuel, which greatly reduces the fuel cost (10 TPD project, consuming about 0.4 tons of pyrolysis oil per day). The water used in the operation of the equipment is recycled water, and the consumption rate is close to zero, so it is negligible.

1.Raw material

It is easy to collect waste plastic in India, many waste plastic suppliers are gathered in one area, and it is easy to find them. They will deliver waste plastic to your door upon request, so you don't need to store waste plastic, which will reduce the pressure on your warehouse. The current market price is about $100/ton. You can even work with your local government to get free scrap plastic.

2. Electricity consumption

One 10 TPD waste plastic to oil plant, which is the most preferred model by our customers, consumes about 300kwh of electricity per day, and according to the feedback from Indian customers, the electricity cost is about $20 per day.

3. Manpower

The waste plastic to oil plant needs three or four people to operate it every day. According to customers’ feedback, the local labor cost is about $10 per person per day.

◆ Revenue of waste plastic to oil project

Revenue comes from 2 main products: pyrolysis oil and carbon black. Depending on the quality of the waste plastic, the yield is about 50%-70% for fuel oil, 20%-40% for carbon black, and 5%-10% for combustible gas. The combustible gas can be used entirely as fuel for heating the pyrolysis reactor.

1. Pyrolysis oil

Pyrolysis oil is a kind of heavy oil, which is a good heating fuel with a calorific value of 10592.48 Kcal/kg, much higher than coal. It has a good market in India. This fuel oil can be widely used in many industrial plants, such as boiler plants, cement plants, steel plants, brick plants, glass plants. The price of pyrolysis oil in India is about $500/ton. If you want to sell the oil at a higher price, you can distill it into diesel oil by Doing pyrolysis oil distillation plant, which has a better market and wider applications in India.

2. Carbon black

The calorific value of carbon black is similar to that of coal, and can be sold directly to carbon black processing plants or made into briquettes for sale. The price for direct selling is about $30/ton.

◆ Profit Analysis of waste plastic to oil project

Daily cost: 10 tons * $100/ton + $20 + 4 people * $10/person + 0.4 tons * $500/ton= $1,260;

Daily revenue: 10 tons * 60% * $500/ton + 10 tons * 30% * $30/ton = $3,090;

Daily net revenue: $3,090 - $1,260 = $1830.

We can see that this project is very profitable.

Actually, waste plastic to oil project has been developed in India for about 10 years and is a very mature project. Again, the government is very supportive because it can solve the plastic waste problem.

Doing Group has sold more than 100 sets of waste plastic to oil plant to India and has a complete business chain in India. If you want to do this project in India, you can contact us anytime and our professional engineers will make the most suitable solution for you.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.