Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

An effective way to deal with waste plastics is to convert waste plastics into fuel oil. This waste plastic recycling method is simple to operate, environmentally friendly and pollution-free. Most waste plastics in daily life are suitable for pyrolysis, but the oil yield will be different, but there are two kinds of plastics that cannot be used for pyrolysis: PVC and PET.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

So what are the plastics that can be used to pyrolysis into oil? For example: pure PE plastic, pure PP plastic, pure PS plastic, pure white plastic cloth, pure white plastic cloth, instant noodle packaging bag, plastic trademark, paper mill waste, plastic household waste, pure plastic cable sheath, clean plastic bag. The oil yield rate of various waste plastics is shown in the figure below:

Different plastics has different oil yield

Different plastics has different oil yield

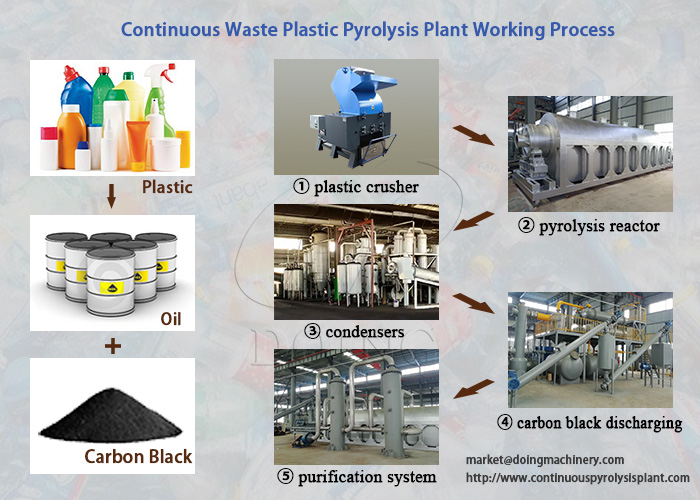

Although the types of these waste plastics are different, their pyrolysis principles are the same. Waste plastic pyrolysis plant is to use the principle of high temperature pyrolysis to convert macromolecular compounds into small molecular compounds under high temperature and oxygen-free conditions, so as to obtain plastic pyrolysis oil, carbon black and combustible gas.

The general process of waste plastic pyrolysis into oil:

1. Feeding of waste plastics: feed waste plastics to the pyrolysis reactor.

2. High-temperature pyrolysis: heating the reactor to a certain temperature, then oil gas will be produced. In this step, special attention should be paid to the heating temperature, and the temperature should be guaranteed to rise steadily, so as to ensure the oil quality and oil yield.

3. Condensation into oil: The oil gas enters the buffer tank to buffer the flow rate and then enters the condensation system for cooling into oil and enters the oil tank for collection.

4. Emission of carbon black: After the heating process of plastic refining, carbon black will be discharged from the slag discharge port.

The process of waste plastic pyrolysis into oil

The process of waste plastic pyrolysis into oil

During the entire process of waste plastic pyrolysis into oil, no harmful substances will be produced to the environment, which can meet the national environmental protection requirements, and the utilization rate of its products is relatively high. The obtained plastic pyrolysis oil can not only be used as fuel for heating in large factories, such as cement factories, steel factories, heavy oil generator, boiler heating, etc. but also can be refined into diesel oil that can be used in more fields by waste oil refinery plants.

If you are also preparing to join the waste plastic pyrolysis industry at this moment, you can contact us at any time, and our project manager of Henan Doing Company can recommend suitable waste plastic pyrolysis plants for you according to your actual situation.

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.