Phone: +86-371-5677-1821

TEL : +86-135-2669-2320

Email: sales@wastetireoil.com

Whatsapp:+86-135-2669-2320

Among the many materials that demand our attention for recycling is corrugated plastic sheeting, commonly used in packaging, signage, and construction. This article delves into the recyclability of corrugated plastic sheets and introduces an innovative solution—pyrolysis technology—that not only aids in their recycling but also converts waste into valuable resource like fuel oil and gas.

Waste pp pe corrugated plastic sheet recycling pyrolysis machine

Waste pp pe corrugated plastic sheet recycling pyrolysis machine

The Challenge of Recycling Corrugated Plastic Sheets:

Corrugated plastic sheets, made primarily from polypropylene (PP) or polyethylene (PE), offer numerous benefits including durability, flexibility, and water resistance. However, these same properties make them challenging to recycle through traditional methods. Most recycling facilities are equipped to process rigid plastics or thin films, leaving corrugated plastics as a less-preferred material due to their complex structure and potential contamination.

However, waste plastic recycling pyrolysis machine offers a groundbreaking method that breaks down organic materials in the absence of oxygen. Unlike conventional recycling, which often involves melting and reshaping, pyrolysis uses heat to convert corrugated plastic sheets into a mixture of pyrolysis oil, combustile gases(syn-gas), and solid residues. This process is particularly effective for plastics that are difficult to recycle using mechanical methods. And the oil yield is as high as 80%-90%.

Waste pp pe plastic recycling pyrolysis machine final products

Waste pp pe plastic recycling pyrolysis machine final products

PP/PE Corrugated Plastic Sheet Pyrolysis Process:

The pyrolysis process of PP/PE corrugated plastic sheet mainly includes the following steps:

1. Feeding and heating: First, the waste plastic will be transported to the reactor of the waste plastic pyrolysis plant, then closed and heated by external fuel (such as fuel oil, gas, coal or wood, etc.). When the temperature in the reactor rises to the cracking temperature of the waste plastic, the plastic begins to decompose.

2. Pyrolysis machine produces oil and gas: Under high temperature, the plastic molecular chain breaks to form a low molecular weight hydrocarbon mixture, namely oil gas. This process is carried out in an oxygen-deficient or micro-oxygen environment to avoid complete combustion.

3. Oil gas cooling and condensation: The generated oil gas then enters the multi-stage condensation system, which usually includes components such as vertical condensers, oil-water separators, and horizontal condensers. The oil and gas exchange heat with the circulating water here, gradually cool and condense into liquid oil, and then flow into the oil tank for storage.

PP PE plastic pyrolysis machine cooling system

PP PE plastic pyrolysis machine cooling system

4. Exhaust gas treatment and recycling: The gas that is not completely condensed, that is, non-condensable gas, will be treated by the tail gas purification and deodorization system to remove harmful substances and odors. The treated tail gas can be recycled and sent back to the reactor as fuel to heat the waste corrugated plastic sheets pyrolysis process, thereby realizing energy recycling and reducing energy consumption.

5. Environmental emissions and by-product treatment: The flue gas generated during the waste PP/PE corrugated plastic sheet pyrolysis process needs to undergo desulfurization, dust removal and other purification steps to ensure that it meets environmental emission standards. In addition, the cracking process also produces carbon black as a by-product, which is a valuable industrial raw material that can be used in rubber, coatings and other fields.

6. Slag discharge and repeated production: When the plastic is completely cracked, the reactor will be cooled, and then the slag discharge port will be opened to collect carbon black using a carbon black collection system. At this point, the entire reactor is emptied and can be prepared for the next round of waste plastic pyrolysis process.

This series of processes not only realizes the effective resource utilization of waste corrugated plastic sheet, but also focuses on environmental protection and efficient energy circulation. Waste plastic recycling pyrolysis machine is a practical example of circular economy and sustainable development.

Benefits of Pyrolysis Machine for Recycling Corrugated Plastic Sheets:

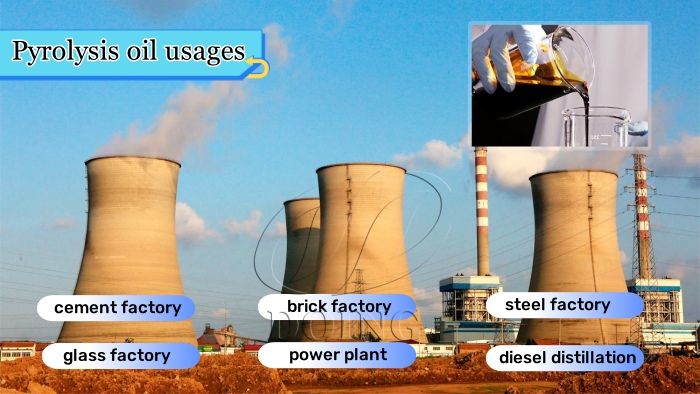

1. Resource Recovery: The oil produced from corrugated plastic sheets into pyrolysis process can be used as heating fuel for various boilers, furnaces, or refined into diesel products for trucks, tractors, ships, boats, fleet, heavy machinery, etc. This not only reduces waste but also contributes to energy independence.

Waste plastic pyrolysis oil applications and refinery

Waste plastic pyrolysis oil applications and refinery

2. Environmental Impact: Pyrolysis significantly reduces greenhouse gas emissions compared to incineration or landfill disposal. It offers a cleaner alternative that aligns with environmental protection standard.

3. Economic Feasibility: By turning waste into commodities, pyrolysis technology creates new revenue streams for businesses and communities. It encourages a circular economy where waste is seen as a resource rather than a liability.

The recyclability of waste plastic like pp/pe corrugated plastic sheets is no longer a question of 'if' but 'how.' With the advent of pyrolysis technology, we now have a viable and sustainable solution that transforms waste plastic into wealth——waste plastic recycling pyrolysis machine.

If have interests in related waste plastic pyrolysis business, welcome to contact Henan Doing Company for a professional pyrolysis solution. We also support to bring your waste raw material to our factory for a testing!

Releate article:

Copyright © 2015-2025.DOING Holdings - Henan Doing Environmental Protection Technology Co., Ltd | All Rights Reserved.